Effective protection from abrasion and corrosion. Highest efficiency thanks to optimized durability.

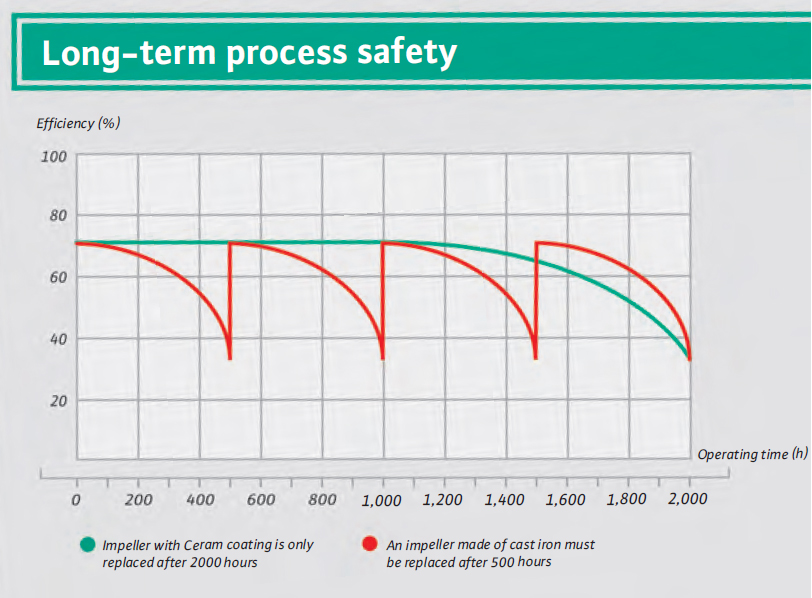

Sewage and sewage treatment plant pumps are constantly being exposed to aggressive fluids. Corrosion and abrasion, as well as UV light, heat, cold, salt, condensate and the alkalinity influence the surfaces and material structures of the units, sometimes with considerable impairment to the performance. This significantly reduces the hydraulic efficiency of a pump (see graph below). This not only results in a higher energy consumption, but also leads to a greatly reduced service life due to the displacement of the load locus for the motor and hydraulics.

A specific application case uses just the example of an impeller coated with Ceram to illustrate the performance and the associated potential for savings. In a kaolin plant, the fluid is so abrasive due to the large amount of very small-grain sand that a cast-iron impeller, which normally has an operating time of about 100,000 hours with no problems,

already had to be replaced after 500 hours of operation. In a test period of 15 months, a total of four cast iron impellers were therefore replaced.

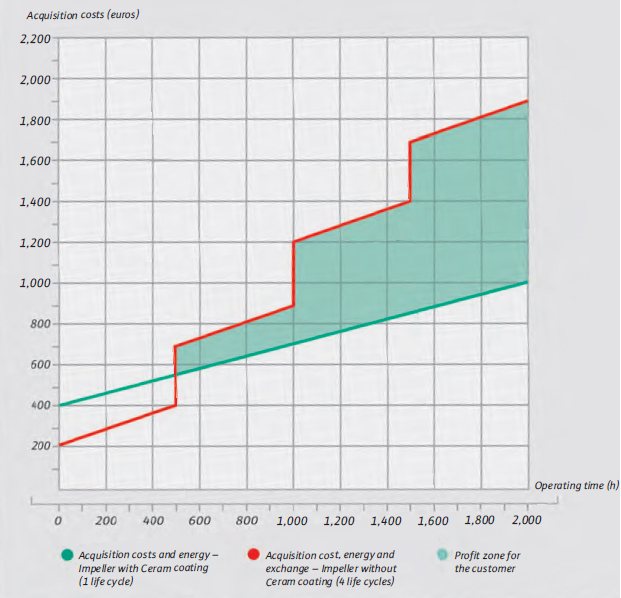

This resulted in the following:

• Acquisition costs

• Loss in efficiency due to the corroded material

• This resulted in increasing energy costs

• Downtimes due to removal and installation

Under the same conditions in exactly the same time period, an impeller coated with Ceram was used. This impeller only had to be replaced after about 2000 hours of operation. The coating could withstand the high mechanical load for four times as long.

If one takes the overall costs over the entire service life of the pump into account, the investment costs for a unit coated with Ceram are less than 11 % and thus negligible. In addition, there is a high savings potential due to fewer repairs being required, resulting in fewer system downtimes. Therefore, a Ceram coating already pays for itself within the first 500 hours of operation, i.e. within the first year.