Capacities from 80 GPM to 15,000 GPM and heads from 10 feet to 400 feet give Cornell a clear performance advantage.

Excellent Efficiencies

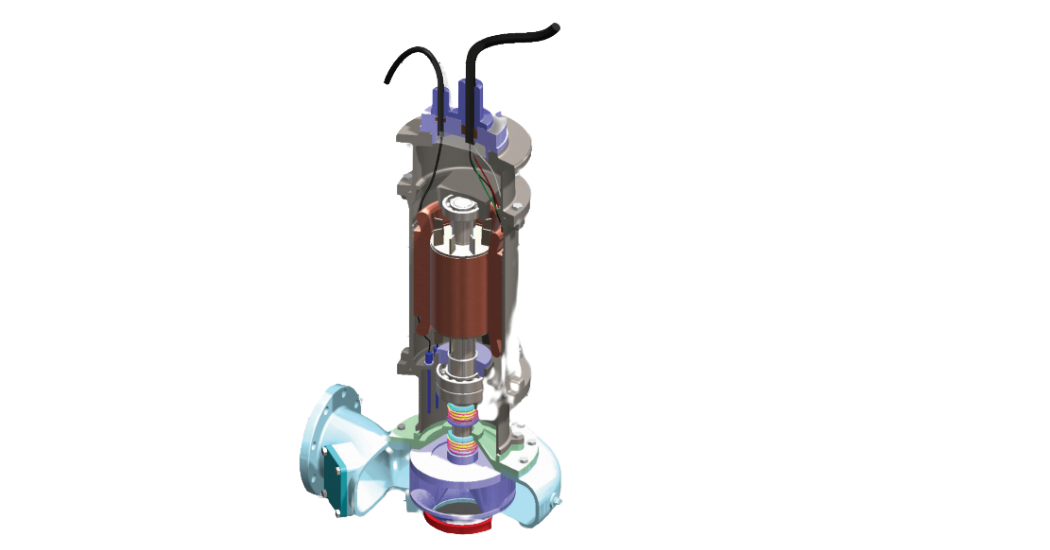

Cornell uses the same high-efficiency pump-ends for our submersibles that have been proven time and time again in standard municipal applications. Coupled with the highest quality motors, Cornell’s submersible product line provides the best possible value. The bottom line – Cornell Submersible Pumps cost less to operate.

Reliable Motor

Cornell understands the need for reliability, durability, and efficiency. This is why they have coupled their pumps with the most reliable and durable submersible motors on the market. Cornell motors are FM approved and suitable for Class I, Division I, Group C & D, explosion-proof service, and are inverter duty. Non-wicking Permanently numbered leads are potted into a separate cable cap assembly, preventing leakage to the stator. Cornell motors are protected by thermostats and utilize class F insulation. Dual moisture probes are installed for the early detection of seal failure. Heavy Duty ball bearings are standard.

Long Life Mechanical Seals

Each pump is supplied with Tungsten mechanical seals and an oil reservoir with moisture sensor probes to provide the maximum protection against damage from leakage. Lower seal is carbon vs. ceramic.

High-Temperature Protection

Motor Temperature protection is embedded in the stator windings to shut the motor down in case of abnormally high temperatures.

Glycol Filled, Closed Loop Cooling

When necessary, Cornell Submersibles can be furnished with a cooling jacket and heat exchanger, filled with glycol, that will protect the motor from overheating during extended periods of low liquid level operation, or when handling high-temperature liquids. Cooling jackets are available on pumps ranging from 10 to 125 horsepower

Rugged Construction

All of Cornell’s submersible pumps come standard with heavy-wall volutes for extended life under abrasive service conditions, smooth passage impellers for optimal hydraulic efficiency and reduced operating cost plus replaceable wear rings and back pull-out design for ease of maintenance. Standard casing and impeller construction is ASTM A48, Class 30 Cast Iron. Special materials are available for high corrosion or abrasive pumpage.