Industry professionals responsible for proper fluid and gas flow are well aware of the importance of check valves. Since many check valves operate automatically and are not under constant human control, choosing the right type of valve is critical.

Every application demands a unique valve; this is particularly true when referring to the discharge side of reciprocating air or gas compressors. Reciprocating compressors, also known as piston compressors, are used in a variety of industrial applications, including:

Reciprocating compressors produce high levels of pressure in order to move gases, so any check valve utilized in this process must be extremely durable and reliable.

At DFT, our team designs, manufactures, and distributes an assortment of check valves to suit even the harshest applications. In order to handle the demands of discharging reciprocating compressors, we have created the unique DFT® Model PDC® Silent Check Valve.

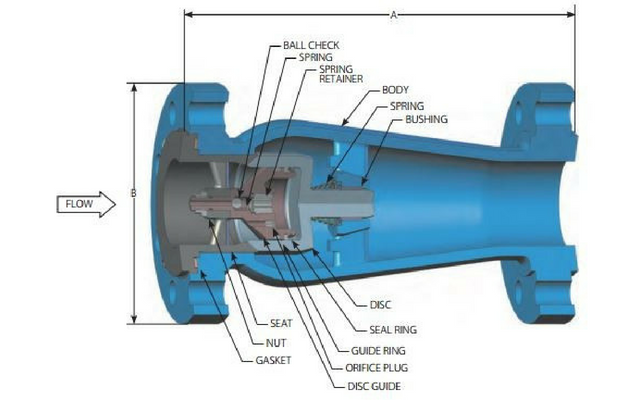

The PDC® valve is a nozzle-style, spring-loaded check valve that allows gases to flow in only one direction. The PDC® valve offers users a variety of benefits; perhaps its most significant feature is its unique pulse damping chamber. The valve’s pulse damping chamber helps maintain the disc in the open position during momentary reductions in flow, which are directly associated with each cycle of a reciprocating compressor. Pulse damping will also protect against costly premature seat wear.

No matter your company’s needs, DFT offers a PDC® Silent Check Valve to fit any application. Our selection of 59 different PDC® Silent Check Valves includes:

*Larger sizes available via factory consultation.

The PDC Silent Check Valve meets several industry standards, including ASME B16.10 (for face-to-face dimensions).

If you need to rely on reciprocating compressors, then the DFT® Model PDC® Silent Check Valve might be the ideal choice for you. To learn more about this one-of-a-kind product, visit our resource library or contact a DFT representative today.