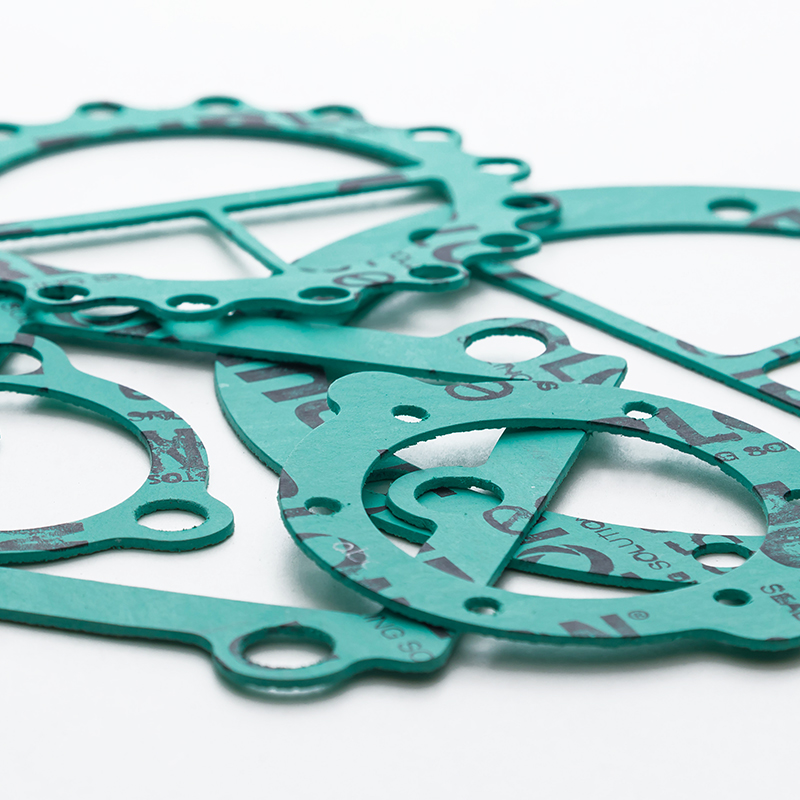

Durlon® 8500 is a high performance compressed gasket material for use in process industries including pulp & paper, food & beverage, pharmaceutical, hydrocarbon, chemical, refinery and general industry. Durlon® 8500 is suitable for oils, water, steam, new generation refrigerants, dilute acids and alkalis and many other liquids and gases. Passed API 6FB Fire Test and conforms to FDA in 21 CFR 177.2600 Rubber articles intended for repeated use.

Application: Durlon® 8500 is excellent in steam, natural gas, soybean processing and with new generation refrigerants. A high quality general service gasket material for use in a wide range of services in pulp and paper, food, beverage, pharmaceutical, chemical, refinery, gas pipeline and general industry. Durlon® 8500 exhibits good compressibility and recovery, excellent sealability, flexibility and cutting characteristics.

Composition: Durlon® 8500 contains high-strength aramid and inorganic fibres bonded with high-grade nitrile (NBR) rubber.

Certifications: Navy Adhesion Test, California Proposition 65, RoHS Reach Declaration, API 6FB Fire Test, FDA Compliant

Physical Properties:

Color: Green

Fiber: Aramid/Inorganic

Binder: NBR

Temperature:

Min: -100°F (-73°C)

Max: 700°F (371°C)

Continuous, max: 548°F (287°C)

Pressure, max: 1500 psi (103 bar)

Density: 106 lbs/ft3 (1.7 g/cc)

Compressibility: 8-16%

Recovery: 50%

Creep Relaxation: 20%

Tensile Strength: 2000 psi (13.8 MPa)

Sealability, cc/min ASTM F2378 (Nitrogen): 0.03

Sealability, ml/hr ASTM F37 (Fuel A): 0.01

Sealability, ml/hr ASTM F37 (Nitrogen): 0.4

Fluid Resistance – ASTM F146, IRM 903 oil, 5 hrs at 300°F (149°C)

Thickness Increase: 0-15%

Weight Increase: 15%

ASTM Fuel B 5 hrs at 70°F (21°C)

Thickness Increase: 0-10%

Weight Increase: 10%

Flexibility, ASTM F147: 10x

Volume Resistivity, ohm-cm, ASTM D257: 4.2 x 1013

Dielectric Breakdown, ASTM D149, kV/mm (V/mil): 10.7 (297)

Gasket Factors:

THICKNESS: 1/16″

m: 2.7

Y psi (MPa): 2359 (16.3)

Gb psi (MPa): 650 (4.5)

a: 0.33

Gs psi (MPa): 200 (1.4)

THICKNESS: 1/8″

m: 4.2

Y psi (MPa): 2931 (20.2)

Gb psi (MPa): 400 (2.8)

a: 0.35

Gs psi (MPa): 20 (0.1)