For the most part, the advantages of variable speed pumping are applicable no matter what type variable speed drive is used. Among these advantages are energy reduction, reduced wear on mechanical components, improved process control, controlled acceleration and deceleration and avoidance of water hammer or hydraulic surges. Eddy Current drives, are different from other variable speed equipment, offering significant advantages not common to all variable speed equipment.

Long service life: Eddy current drives can be expected to remain in reliable service for several decades, matching the service life of the motor and the pump for which they are used.

No power source harmonic distortion: Because the motor runs directly from the electric utility supply at constant speed, there is no electronic conversion of the power that would generate harmonic interference. Therefore, no harmonic study is warranted, and no auxiliary equipment is needed for harmonic mitigation.

No harmonics in the motor circuit: The motor runs at constant speed without any high frequency voltage pulsations, which are known to induce elevated shaft voltage. In turn, this leads to bearing damage as the voltage finds a path to ground through the anti-friction bearings.

Audible noise: Eddy current drives produce minimal noise in operation and don’t affect motor noise.

Long leads: If necessary, the rotating mechanical equipment can be located several thousand feet from the control equipment without any special consideration.

Air conditioning unnecessary: Losses produced are dissipated by the rotating drum, turning at constant motor speed. Ambient air is almost always sufficient in volume to absorb and dissipate this heat, so no special cooling equipment is needed.

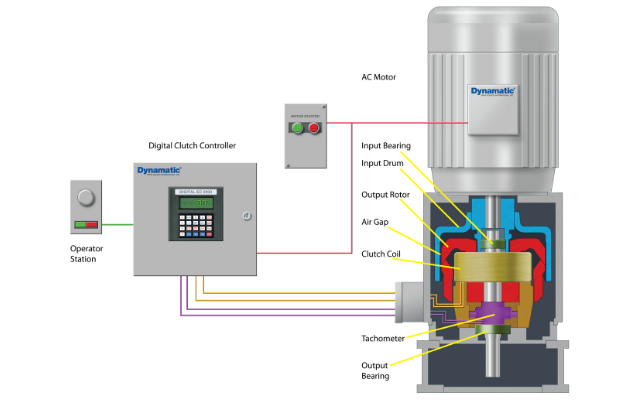

Small footprint: Eddy current drives are easy to retrofit to existing equipment, especially vertical units. The added height is usually easy to accommodate, and the small wall-mounted enclosure for the controller is normally 30 inches by 36 inches.

Simple to diagnose and repair: Generally, eddy current drives can be repaired by local service organizations. Factory assistance is available to facilitate such repairs if necessary.

Obsolescence: Rotating mechanical designs are largely unchanged for decades. Controls are available for any eddy current drive ever made.

Low-end torque: An eddy current drive can easily deliver all the torque available from its drive motor at any speed, including zero. This is a significant advantage for starting certain loads, especially positive displacement pumps that have a residual load of pumped material within the pump.

Eddy Current Drives have been in widespread use for variable speed pumps and blowers for nearly 70 years and continue to be the best cost-effective variable speed solution in wastewater treatment plants and pumping stations. DSI/Dynamatic is the leading authority of eddy current proven technology, which is well suited for today’s industries and modern client base. Get more information about our specialized total system by contacting us or visiting Dynamatic at this year’s WEFTEC in New Orleans October 1-3 in booth 6049.