TF-LEX – NEW!

Thermafoil TF-LEX is a low load flexible graphite laminate with excellent blowout and scrubbing resistance. It is a laminated material made with Thermafoil Grade K (TF-K) flexible graphite bonded to both faces of a .005” thick, stainless steel expanded metal insert. TF-K is an industrial gasket grade, monolithic, flexible graphite sheet material containing no binders with an added non-metallic, inorganic, passive oxidation/corrosion inhibitor. TF-LEX requires a much lower seating stress than other graphitic gasket materials and meets most automotive and industrial fluid sealing service requirements. This material will seal a wide variety of liquids and gases over a wide range of temperatures.

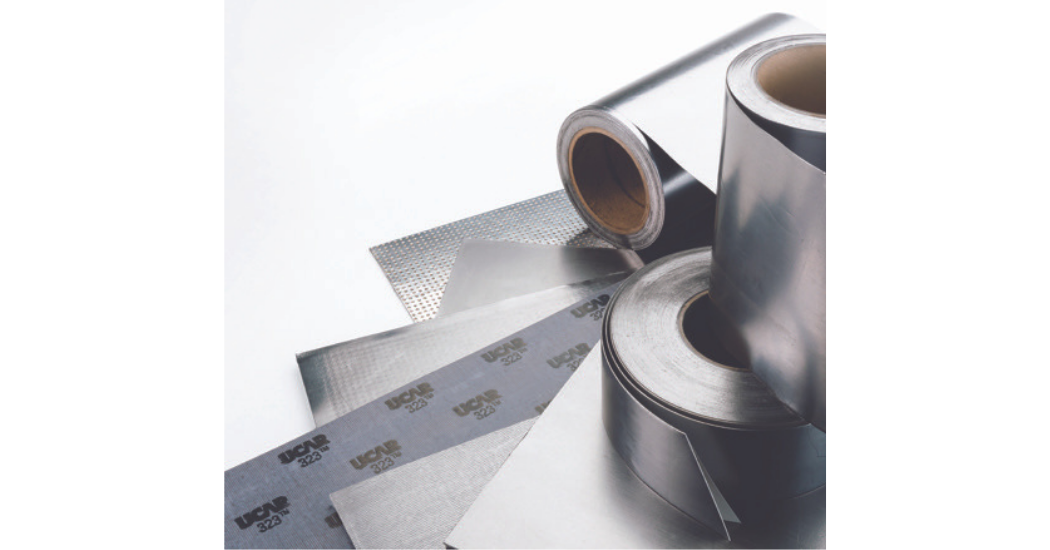

TF-LAP Sheet and Rolls

Thermafoil TF-LAP (Alta Pressione) is a high strength laminate material comprised of alternating layers of industrial grade K graphite foil and a .002” (0.5mm) thick 316 or 321 stainless steel foil. The thick layers of graphite contain an inorganic, non-metallic, passive oxidation/corrosion inhibitor. TF-LAP has an excellent blowout resistance and is well-suited to handle gasket pressure over 40,000 psi and internal pressures up to 3,500 psi. It has carbon content greater than 98%.

TF-LHR

Thermafoil TF-LHR is a metal reinforce laminate consisting of multiple layers of flexible graphite material adhesively bonded with .002”, 300-series stainless steel foil. Using A grade flexible graphite, the laminate is suitable for nuclear applications. Using C-grade flexible graphite, the laminate works in automotive exhaust systems and other high-temperature industrial applications.

TF-LHT or TF-A or TF-J

Thermafoil TF-LHT is a flexible graphite consisting of Grade B (carbon content of 98.2%) flexible graphite and adhesively bonded to a Hastelloy C-276, .002” metal insert. The laminate is non-fibrous, non-asbestos and provides high temperature and chemical resistance. The laminate can also be made with Grade A (nuclear grade carbon content of 99% or greater) or Grade J (carbon content greater than 99%) material.

TF-Ni-K

Thermafoil Ni-K flexible graphite is an uncured laminate made with Grade K flexible graphite sheets at a nominal 90lbs. per ft. density. Sheets are adhesively bonded on both sides of a .003” thick, fully annealed Nickle 100/201 foil insert. A heat activation process is required to cure adhesive on laminates less than 26” x 26”. Laminates greater than 26”x 26” require no heat activation.

TF-LHS

Laminated material made from Thermafoil Grade B flexible graphite, with a 70lb/ft3 nominal density, bonded to a .0025”, 316 stainless steel wire mesh (150 mesh) insert, bonded with a carbon based thermally activated adhesive. The mesh provides outstanding tensile strength and creep resistance.

TF-LHE

Laminate material manufactured with Thermafoil Grade B flexible graphite with 70 lb/ft3 nominal density and mechanically bonded to both faces of .004” or .005”, 316 stainless steel tang metal insert. Thermfoil Grade TF-LHE meets most industrial fluid sealing service requirements and is available in sheets or rolls.

TF-LHJ

Laminate material made from Thermafoil Grade C flexible graphite, mechanically attached to a perforated low carbon steel core. Available in standard widths of 24” (610mm) and standard lengths of 39.4” (1000mm). Non-standard dimensions are available by request.

EGC: An Engineering Company

Engineering is what distinguishes EGC from other flexible graphite products. A thorough understanding of flexible graphite is part of our core philosophy— it’s not the material properties, but the engineering and manufacturing process that enables flexible graphite to seal in the toughest conditions.

Since 1978, we have been a world leader in Thermafoil® Flexible Graphite and other composite materials; crafting them into solutions for high temperature and severe service applications. Our proprietary knowledge allows us to provide custom solutions where tensile strength, oxidation, or high vibration challenges are present.

From reducing wear on valves, pumps, boilers, and piping equipment in power plants to reducing fugitive emissions in petrochemical and refining plants around the world, EGC’s flexible graphite product solutions reduce consumed energy, eliminate harmful emissions, and increase the value of your critical assets.

Single Layer Materials

TF-A

Thermafoil Grade A is a premium, monolithic, flexible graphite sheet material containing no fillers or binders. It is certified to meet the most rigorous purity specifications of the nuclear industry including the U.S. Navy Mil-Spec. MIL-P-24502B (SH), and the General Electric Nuclear Nonmetallic Material Specification D50YP12 (Rev 2). It has a carbon content greater than 99%.

TF-B or TF-K

Thermafoil Grade B or K are standard industrial, monolithic flexible graphite materials with a minimum purity level of 96%. Grade K contains added oxidation/corrosion inhibitors. These materials will seal a wide variety of fluids over a very broad temperature range. The typical carbon content of 98.2% is common.

TF-C

Thermafoil Grade C is an automotive-grade, monolithic, flexible graphite sheet material containing no binders. It has a carbon content greater than 95% and can reach temperatures from -400°F to 850°F (-240°C to 450°C).

TF-X

Thermafoil Grade C is an automotive-grade, monolithic, flexible graphite sheet material with extraordinary oxidation resistance. It has a carbon content greater than 95% and can reach temperatures from -400°F to 850°F (-240°C to 450°C).

Homogeneous Laminates

TF-LA or TF-LB

Gasket grade industrial, cured, adhesive bonded, homogeneous laminate made from Thermafoil Grade A (nuclear grade carbon content of 99% or greater) or Grade B (carbon content of 98.2%). It is heat treated to carbonize and degas the adhesive. The materials will seal a wide variety of liquids and gasses over a large temperature range.

TF-LL-A or TF-LL or TF-LC

Thermafoil LL-A, LL, or LC is an uncured, homogeneous laminate made with Grade A (nuclear grade carbon content of 99% or greater), B (carbon content of 98.2%), or C (carbon content greater than 95%) flexible graphite sheets adhesively bonded together. TF-LL-A is 98.8% pure, which makes it the logical choice for nuclear applications including General Electric Nuclear Nonmetallic Material Specification D50YP12 (Rev 2).

Non-Metal Reinforced Laminates

TF-LL

Thermafoil TF-LL flexible graphite is an uncured, adhesive bonded, homogeneous laminate made with Thermafoil B flexible graphite sheets. TFLL contains an oxidation and corrosion inhibitor that allows for continuous use in temperatures ranging from -400°F to 975°F (-240°C –525°C). This reduces the potential for galvanic corrosion when in contact with steel or stainless steel. Carbon content is 98% minimum.

TF-LHW

Laminate material made with Thermafoil Grade B flexible graphite, with 70 lb/ft3 nominal density bonded to a .003” to.004” thick, woven fiberglass cloth insert with a carbon-based thermally activated adhesive. Grade TF-LHW provides excellent blowout resistance along with excellent strength and handling characteristics. Carbon content is, at minimum, 98%.

TF-LTH

Adhesive-backed industrial sheet or tape made with standard nominal 70lb Thermafoil Grade B flexible graphite, adhesively bonded to .005” thick polyester carrier with a .0012” thick acrylic pressure sensitive adhesive face. The adhesive face is protected with silicone treated release paper. Carbon content of TF-LTH is 98%.

TF –LHP

Laminate material made with Thermafoil Grade B flexible graphite sheets chemically bonded to the top and bottom of a 0.0015” thick plastic film insert by an adhesive of not more than 0.0003” thick on either side that will carbonize when subjected to heat. TF-LHP has no fillers, binders, or asbestos content. It has a carbon content of 98% ppm maximum per ASTM C-571.