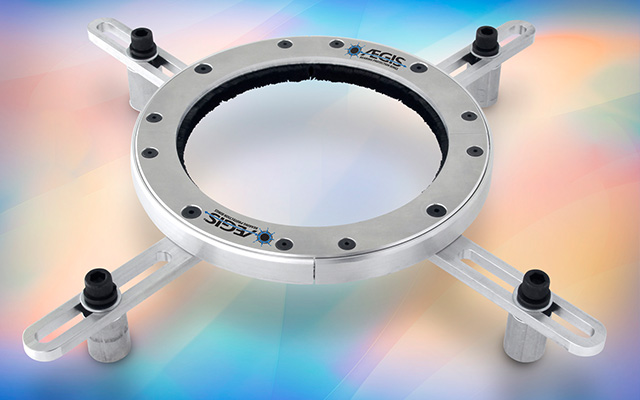

New Universal Mounting Brackets allow fast, easy installation of AEGIS® PRO Series, AEGIS® PROMR, and AEGIS® WTG Bearing Protection Rings on large motors. Attached to PRO Series or WTG Rings with screws, these specially designed brackets have slotted legs for mounting, allowing bolt circles of 2.64” to 7.79” greater than the shaft diameter. Brackets are provided with 1/2”, 1”, and 1-1/2” standoff spacers to provide sufficient clearance for shaft shoulders, slingers, or other end bell protrusions. Mounting bolts, flat washers, and lock washers are also included.

Available for motor shafts to 30” in diameter, rugged, highly reliable, and maintenance-free AEGIS® PRO Series Rings prevent electrical bearing damage that could lead to the failure of medium-voltage motors or generators, unplanned downtime, costly repairs, and lost revenues. To facilitate field retrofits, PRO Series split-rings come in mating halves that simplify installation around the shafts of coupled equipment. AEGIS® PRO Series Rings are ideal for medium-voltage motors that drive pumps, compressors, mixers, shredders, conveyors, and other machinery used in mining, food processing, wastewater treatment, petrochemical refining, and other applications. They are also ideal for protecting the bearings of generators in both utility and on-site power generation systems.

The AEGIS® PROMR combines a PRO Series Bearing Protection Ring with a shaft voltage monitoring ring in a single compact unit. It ensures maximum uptime and reliability of large motors and generators in critical applications, and enables real-time monitoring of shaft voltage levels on motors in remote or hard-to-access locations.

The AEGIS® WTG Ring prevents electrical bearing damage to wind turbine generators. Designed for OEM installation or easy up-tower retrofit, the WTG safely diverts up to 120 amps of continuous shaft current at frequencies to 13.5 MHz, as well as discharges to 3000 V (peak).

Without shaft grounding, shaft voltages induced by variable frequency drives (VFDs) discharge through the bearings of motors, generators, and coupled equipment. AEGIS® PRO Series and WTG Rings have six rows of conductive microfibers that completely surround the motor shaft, providing millions of discharge points for harmful shaft currents and creating a path of least resistance away from bearings to ground.

DOWNLOAD OUR FREE HANDBOOK: Best Practices for Bearing Protection

DOWNLOAD OUR FREE HANDBOOK: Best Practices for Bearing Protection

Our 56-page handbook describes the causes and symptoms of VFD-induced bearing damage and shares best practices for protecting motors against VFD-induced bearing damage.

For more information, contact: Adam Willwerth, Sales and Marketing Manager, Electro Static Technology, 31 Winterbrook Road, Mechanic Falls, ME 04256, Toll-Free: 1-866-738-1857, TEL: (207) 998-5140, sales@est-aegis.com, www.est-aegis.com.