Features:

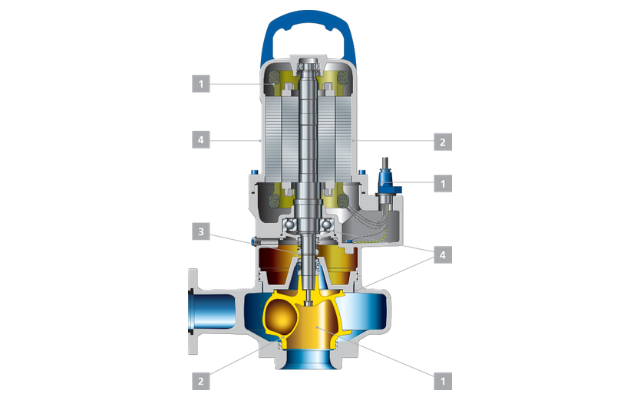

1. Reliable Operation

- Non-clogging impellers with large free passages, optimized for every type of wastewater

- Specially protected cable entry

- Advanced monitoring sensors

- Monitoring: Sensors trigger a warning in the event of overheating or ingress of moisture

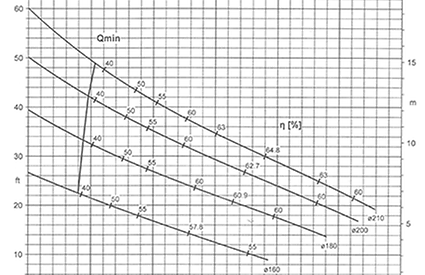

2. Energy Savings

- Optimized hydraulic system yields high efficiency

- Energy-saving motors meeting IE3 requirements

3. Dependability

Two bi-directional mechanical seals

4. Cost Efficiency

The right material for every liquid. Available in grey cast iron or, optionally, in corrosion-resistant duplex stainless steel or wear resistant white cast iron for a long service life

Rolling element bearings are lubricated for life to reduce maintenance

Optimized spare parts inventories: Standardized components are interchangeable within this type series and with the waste water pumps of the Sewatec type series

5. Flexibility

Various installation types to suit different building structures

Applications

- Municipal and industrial wastewater

- Wastewater transport

- Wastewater treatment

- Sludge treatment

- Stormwater transport

| Technical Data |

|

| Sizes |

1-1/2 TO 28 in. |

| Capacity |

Up to 44,000 gpm. |

| Head |

Up to 394 ft. |

| Fluid pressure |

Up to 140°F |

| Automation possible |

Yes |

- Explosion-proof to NEC 500, Class 1, Division 1, Groups C and D, T3, hazardous (classified) locations.

- IEC 60034-30 standard not binding for submersible motors. Efficiencies calculated/determined according to the measurement method specified in IEC 60034-2. The marking is used for submersible motors that achieve efficiency levels similar to those of standardized motors to the IEC 60034-30 standard.