GAS TOLERANT TWIN SCREW PUMP

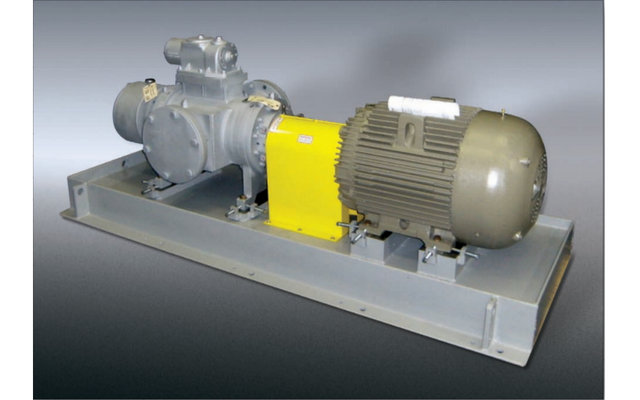

The Leistritz Flare Knock-out pump is a timed twin-screw pump with replaceable liner, integral shafts and external bearings. The design and material composition are suitable for pumping materials that can be corrosive, abrasive or flammable.

FLARE KNOCK-OUT PUMPS – GAS TOLERANT TWIN SCREW PUMP

FLARE KNOCK-OUT PUMPS – GAS TOLERANT TWIN SCREW PUMP

Performance

Screw pumps are relatively simple pump designs with few moving parts. They have low NPSH requirements, exceeding those of vertical can pumps, handle a wide range of viscosities, and operate with no vibration despite entrained gas.

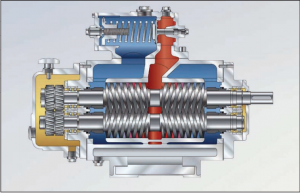

Non-Contacting Rotors

The double-flow rotors are hydraulically balanced. Pump fluids fill the voids between the rotors and the liner to seal the pumping chambers and transport fluids, including gas, from suction to discharge. The twin-screw design produces a constant, non-pulsating flow and eliminates problems with vapor locking. This pump tolerates frequent starts and stops and can operate dry for periods of time.

Seals and External Bearings

The rotors are supported at both ends by external, oil-lubricated bearings. Each shaft penetration is sealed with double mechanical seals and utilizes the API Plan 53B or Plan 54 seal flush system. Timing gears transmit torque between the drive and driven rotors.