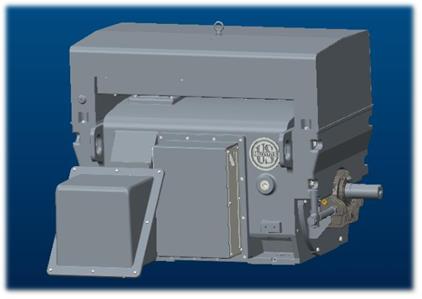

Nidec Motor Corporation (NMC) today announced a redesign of its U.S. Motors® brand TITAN® II Open Drip Proof (ODP), Weather Protected Type I (WPI) and Weather Protected Type II (WPII) 5000 frame horizontal motors that will enable adaptable mounting for increased field convertibility.

The new TITAN II 5000 frame motors allow for five different mounting positions with height adjustments for the conduit box for field matching of the existing motor being replaced. The motors come with tri-drilled holes for feet mounting. They are capable of IEC 315 frame mounting, and also available as designed, built and tested to API 547 Standard with optional API®† Monogram nameplate. A top mounted conduit box is also available on all TITAN II WPI motors.

The ODP/WPI and WPII motors are field convertible from F1 to F2 without disruption of the motor. ODP/WPI motors can also be modified for F3 assembly position.

“We are continually looking for ways to make great motors better,” said Nidec Director of Marketing and Product Management Tim Albers. “With this redesign, our distributors are able to offer a motor that will increase their end users’ ease in replacing and installing motors, and will provide them with more flexibility.”

Made with robust cast iron construction to minimize internal stresses and vibration, TITAN II motors are suited for use in the petrochemical, pulp and paper, wastewater, electric power, steel, forestry, cement and mining industries.

The TITAN II 5000 frame motors can be provided with an industry-leading, self-contained sleeve bearing system. They are available for order, and are being manufactured and assembled in Mena, Arkansas.

For more information about U.S. MOTORS, please visit www.usmotors.com.