Precision Polymer Engineering (PPE), one of the world’s leading manufacturers of high performance molded elastomer seals, has broadened its range of advanced sealing solutions aimed at high pressure, oil & gas applications.

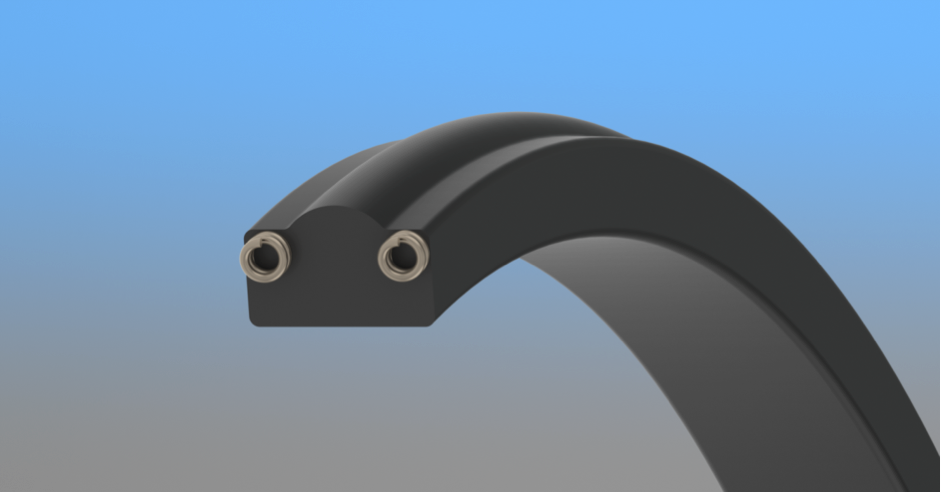

The new product line is a range of spring seals; elastomer seals with incorporated springs that act as an anti-extrusion device. The spring seal design can replace a T seal and backup rings and are suitable for applications with high pressures, high temperatures, aggressive media and environments. These seals are uniquely available from PPE in their Perlast and EnDura materials, making them invaluable in extreme environments and applications such as downhole, wellhead, surface equipment and high pressure pipelines, riser systems and other high pressure applications.

These new seals incorporate a two internal springs which can be made from Inconel Alloy, stainless steel or PEEK. The springs prevent the extrusion of the seal when pressure is applied thus maintaining the integrity of the seal under extreme pressure. The PEEK version of the springs eliminates metal to metal contact, reducing wear and extending the operational lifetime of equipment using this type of seal.

PPE will be providing customized seal combinations not currently available from any other manufacturer with an industry-leading rapid delivery service designed to reduce inventory and to serve the needs of development projects. With the high quality that customers have come to expect from PPE, clients will also experience less downtime and a lower risk of failure from using the PPE spring seals.

PPE’s spring seals will be available from 60mm to 850mm (2½” to 33½”) internal diameters and between 3.53 and 8.4mm (0.14” to 0.33”) cross sections.

To find out more about the latest new materials from PPE, please visit www.prepol.com , telephone USA 713-482-0123, Europe +44 (0) 1254 295400 or email prepol.sales@idexcorp.com