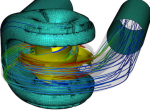

Simulate pumps and valves with the accuracy of hardware testing using the CFD test bed, PumpLinx. Developed for the pump engineer, PumpLinx goes from CAD to simulation in less than twenty minutes. Look inside the pump. Analyze pressure, flow dynamics, cavitation and aeration. Include leakages and detailed features. Include the effect of compressible air. Simulate transient effects and off-design. Reduce hardware testing. Improve performance, avoid cavitation, and decrease noise. Ask for a free demo!

Learn more about virtual pump testing: http://www.simerics.com/