Up to 80% Energy Savings!*

Energy is a valuable commodity. This is why Wilo created the world’s first high-efficiency circulator in 2001. With the help of ECM technology, this efficient, functional and flexible pump for heating, cooling, and air conditioning reduces annual power consumption by up to 80%. Standing for Electronically Commutated Motor, ECM essentially comprises a synchronous motor with a permanent magnet rotor. The unique rotor-stator construction helps eliminate electrical losses.

Applications:

- Hot Water Heating Systems

- Closed Cooling Circuits

- Air Conditioning Systems

- Solar / Geothermal

Features & Benefits:

- EC motor technology reduces energy consumption by up to 80%

- ‘Red Button’ technology and LEDdisplay

- Lead/Lag operation with auto 24-hr alternation

- Dual-volute design cuts installation costs by up to 50%

- Optimized peak load operation

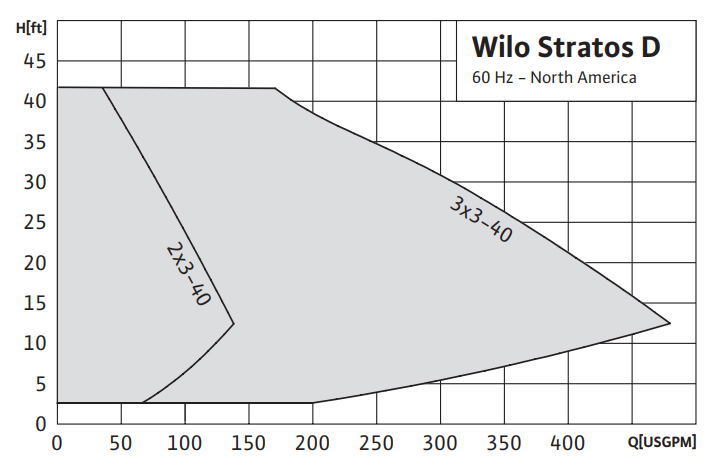

Technical Data:

- ΔP-V, ΔP-C, ΔP-T speed control or external signals with IF module.

- Temp Range: 14°F to 230°F (-10°C to 110°C)

- Electrical Connection: 1~230v (+/- 10%)

- Max flows: 480 USGPM

- Max Head: 43 feet

Materials of Construction:

- Cast Iron, Cataphoresis Coated Volute

- Composite Impeller

- Stainless Steel Shaft

- Carbon, Metal Impregnated Bearing

Compatible with IR Device & IF Modules

*Compared to an uncontrolled circulator.