There are so many talented and interesting people working in the pump industry that Empowering Pumps is making an effort to shine a spotlight on individuals who spend their time and energy making valuable contributions within the Pumping Industry.

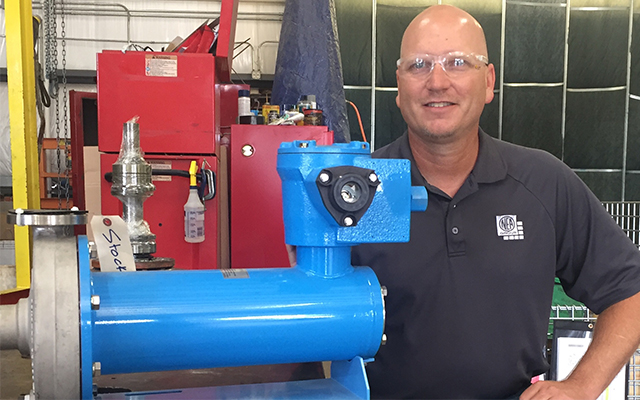

At the Gulf South Rotating Machinery Symposium, Empowering Pumps met up with Lane Lousteau, Account Manager with NEAC Compressor Service USA, Inc., where we learned about his transition into the chemical processing industry and his experience working with pumps and compressors.

Q: How did you get started in the Pump Industry?

Lane: Well, I currently work for a reciprocating compressor manufacturer in aftermarket sales and support, but I initially went to college for aircraft maintenance. I started as a helicopter mechanic and worked for Chevron Oil Company, supporting their offshore aircraft operations. Then I moved to Dow Chemical to work as a millwright, and the mechanical experience I had from the aviation side really translated well into my work as a rotating equipment mechanic for Dow. After 3 years, I had the opportunity to become the Rotating Equipment Specialist for my area. I was intimidated at first because there was a lot to learn. As a mechanic, I didn’t really learn about how to troubleshoot pump hydraulics. I learned to see the symptoms and how to recognize when there’s a problem. I now had to learn how to troubleshoot the entire pump system. Learning and understanding how the system resistance, system layout and the chemical makeup of the fluid affect the reliability pumps was very important for me. I never would have been able to learn that side of it as a mechanic. Knowing and understanding the application of it was also important – because at that point, I had already been proficient with things like shaft alignment and the installation and setting of all types of mechanical seals. The experience that I gained as a Millwright and as a Rotating Equipment Specialist really helps me in my current role.

Q: How did you ‘jump’ from working with pumps to compressors?

Lane: I was actually learning about compressors at the same time – it was all part of my area of responsibility. At one point, I was responsible for almost 500 pumps and 7 reciprocating compressors! Recip compressors are usually larger than pumps and they typically require a lot more effort, more manpower and more planning for the most part. Compared to the average pump, a reciprocating compressor can cause more problems! I worked on pumps every day, but I only worked on compressors two or three times a year; and when I did, it took a lot of time, effort, and energy! There was significant effort put into lengthening the run times and increasing the reliability of our reciprocating compressors.

Q: What’s your favorite part of your job?

Lane: My favorite part of my job is the interaction with the people. Many of my customers are fighting the fires that I used to fight, and I understand the stresses and pressures to keep equipment running. Being able to help find solutions to get equipment repaired and back into service is something that I really enjoy! I spend a lot of time on compressors now, but I do talk pumps often with customers as well. When I’m in a customer’s office, I can tell what they’re working on by what they have out on their desk; and more times than not, it’s a pump or a seal that’s taking up their time. So I wind up talking pumps and seals as much as I talk compressors.

Q: What would be your advice to a new or young person considering working in the Pump Industry?

Lane: When I made the decision to leave the helicopter industry it was a difficult one. I wasn’t sure if it would be a good fit for me. I was given the opportunity to become a Millwright for Dow because the hiring manager at the time believed that the skills that I developed as an Aircraft Mechanic would help me to succeed as a Millwright. He was a Manager that would focus more on the competencies, talents, and capabilities of individuals than on their level of experience with any particular role. I learned a lot from him and others willing to share their knowledge and experience, so the important point here is that everyone in this industry has something to teach and something to learn from one another. Don’t be afraid to enter an industry with little experience, because with a willingness to learn and a high level of effort, you can be very successful!

Lane, thank you for your contributions to the pumping community! Keep us posted of any great training opportunities that you come across so we can share them!

Know an Amazing Person who is making valuable contributions within the Pump Industry? Nominate them to be “Pump Person of the Week”!

Know an Amazing Person who is making valuable contributions within the Pump Industry? Nominate them to be “Pump Person of the Week”!

I think, this is a good person for become “Pump Person of the Week”. He is professional in different kinds of rotating equipment, in pumps & compressors, etc. It is pleasure to see the good high level profi like myself!

[…] Compressor Person of the Week – Lane Lousteau […]