Slurry: “A suspension of solid particles in a liquid.”

It sounds easy if you say it quickly, but in fact the term “slurry” can cover a wide combination of liquid and solid products and waste material that can be either relatively simple to pump or extremely difficult; depending on the mixture.

One of the key elements in slurry pumping is the size and nature of the solids being transported by the water and the nature of the abrasive wear it causes. As wear is a function of velocity, the pumps usually operate at 1200 rpm or slower.

The centrifugal pumps used in slurry handling are basically conventional water pumps modified in a variety of ways to handle the particular solids. While some of these modifications are minimal, some of them are quite extensive. The difference depends on the size and nature of the solids being handled.

Although the emphasis on a slurry pump tends to be on the size and percentage of solids to be moved, it should be remembered that many of these slurry applications are in services where corrosion resistance is also a factor. In such cases, material selection for corrosion resistance needs to be combined with the pump style selection.

Industrial Slurries

In general industry where water run-off in the plant may drain to a central sump and is then pumped out to a collection tank, the solids in the water usually represent plant debris and tend to be quite small. As they also represent a low percentage of the total volume, the slurry can usually be handled by a conventional centrifugal sump pump. The specific pump design in these services can be quite varied, but the traditional vertical submerged suction sump pump and the submersible pump are both widely used.

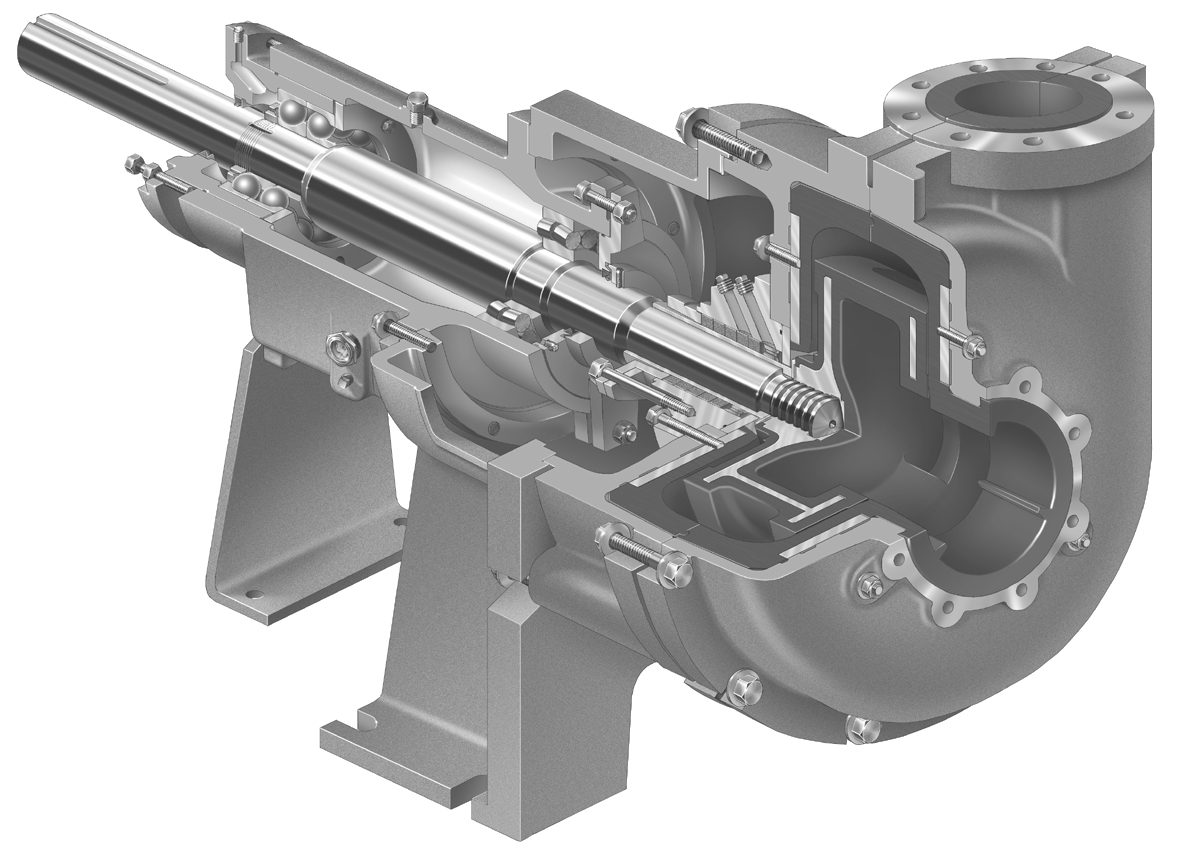

For special industrial applications a variety of pump designs have been developed. A popular option to the large closed impeller in some industries is the open impeller that operates with a tight clearance against a casing fitted with sacrificial wear plate as shown in Figure 1.

Figure 1: Solids Handling Pump with Wear Plate

Municipal Waste

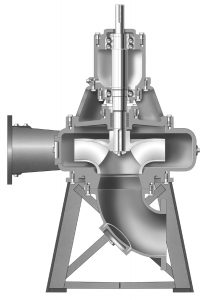

In municipal waste management applications, horizontal and vertical solids handling pumps are designed with the capability of handling specified spherical diameters. A few models of such pumps will have an open impeller while many will be designed with closed impellers having the necessary clearance between the vanes of the impeller and also between the shrouds.

For example, a 4 inch pump would have the ability to pass a 4 inch sphere through the impeller. The same pump would have at least a 4 inch diameter suction nozzle and a 4 inch diameter discharge outlet. This type of pump defies the normal design custom on a centrifugal pump of having the discharge being one size smaller than the suction. Such a design would run the risk of plugging the discharge with a solid that can be handled by the suction nozzle and impeller, but be too large for the smaller discharge nozzle.

In spite of the focus on the solids size in the selection and purchase of pumps for municipal waste, the major problem in these pumping applications tends to be the stringy material. This material can invade the eye of the impeller, wrap itself around the shaft nut, and eventually clog the pump.

Pipelines and Mines

These applications usually require very large pumps that are subjected to high levels of abrasive wear of different types.

• Gouging abrasion occurs when coarse, angular particles

tear fragments of the wearing surface.

• Grinding wear as a result of fine particles being crushed

between two surfaces in close proximity, such as at the

clearances between the impeller and the front and back

wear plates, or the casing itself.

• Erosion abrasion caused by the impact of solid particles on

the wearing surface at high velocity.

Tough materials of construction are necessary in most of these applications and include metal liners and/or wear plates with Ni-Hard and heat-treated high chrome iron. Natural rubber and other elastomers are also frequently used as a liner for abrasive services as long as they are chemically compatible with the slurry.

It is worth noting that hard metal and rubber impellers cannot be machined to the necessary diameter in order to meet the required operating conditions. Consequently, they have traditionally been belt-driven and a change in operation is achieved by a change in sheave ratio to give the rotational speed required.

Recessed Impeller Vortex Pumps

In most slurry, the water tends to be used simply as a mode of transport for the solid particles that usually impart the damage to the pump. This is when the special materials are required for the casing and impeller to resist such attack as discussed above.

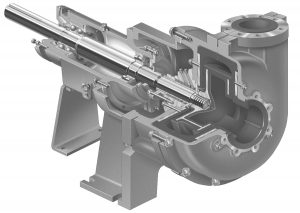

However, there are also those conditions where the solids part of the slurry is the important part and needs to be protected from the damaging impact within the pump. For such applications, a popular option is the recessed impeller (or vortex) design shown in Figure 4.

This style locates the impeller in a recessed position in the casing out of the normal flow pattern in the pump. The impeller develops a vortex in the fluid inside the pump casing so that most of the solids never touch the impeller. While this tends to reduce the wear on the impeller, it also minimizes any damage to the solids.

Progressive Cavity Pump

The Progressive Cavity pump has recently developed a place in the slurry market for delivering smooth, non-pulsating flows. These pumps are particularly effective when pumping thicker sludges with limited amounts of small solid particles. They usually operate at less than 300 rpm. to minimize wear.

The Slurry Mixture

Where pumps are to be applied to mixtures that are both corrosive and abrasive, the predominant factor causing wear should be identified and the materials of construction selected accordingly. This often results in a compromise and in many cases can only be decided as a result of test or operational experience.

For any slurry pump application, a complete description of the mixture components is required in order to select the correct type of pump and materials of construction.

Comments