Normally the user shouldn’t have to care about axial thrust. Pump failure from an axial thrust-related problem is relatively uncommon. But very few, if any, pumps are entirely immune to this class of problem.

Why is this? First of all, a rotating single-entry impeller wants to move in an axial direction and usually with lots of force. And while the principles of axial thrust are easy to understand, there are a variety of complicating factors and uncertainties, any one or combination of which can lead to an axial thrust problem.

It is instructive to consider the magnitude ofacting on an impeller. A 12 inch (305 mm) diameter radial impeller operating at 3580 rpm in cold water may have 16,000 lbs (71 kN) of force acting on its rear shroud and 13,000 lbs (58 kN) plus or minus, depending on eye ring diameter, acting on its front shroud.

These are significant forces. In terms of physical objects we can relate to, the forces in each opposing direction are equivalent to the weight of 2 or 3 full-size pickup trucks acting against the single 12 inch (305 mm) impeller. On a larger diameter impeller or at higher speeds these forces increase by approximately the square of the ratio of diameters or speed. For instance at a pump speed of 4500 rpm this equates to 4 or 5 full-size pickup trucks in each direction.

The net axial thrust of the impeller is the difference between forces acting on back and front shrouds. There are a number of difficult-to-quantify hydrodynamic effects that can alter these forces. For instance, ring leakage or impeller axial positioning relative to the volute or diffuser can alter the pressure distribution between the impeller and sidewall gaps. Relatively small changes in pressure are greatly magnified by the large projected shroud surface areas. The result can be very large shifts in axial thrust in either direction.

The operating flow of the pump relative to BEP also plays an important role. Axial thrust increases substantially towards shutoff and can reduce to the point of thrust reversal at runout flow. For multi-stage pumps these forces are additive. The combination of uncertainties in addition to the range of pump operating conditions, plus internal wear and leakage effects can exceed the design capacity of the thrust bearing.

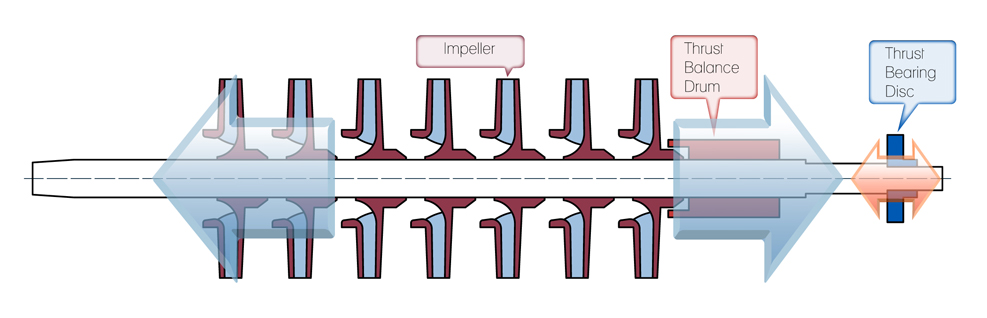

On a typical single stage pump, thrust compensating features such as a back wear ring and balance holes or back pump-out vanes are designed onto the impeller. A double suction impeller has theoretically zero net axial thrust and in practice it is a relatively small value. On multi-stage pumps of in-line single entry impellers the residual axial thrust is normally compensated by a balance drum, balance disc, or combination drum-disc device. Even with opposed impellers, the multi-stage rotor is still normally fitted with a thrust compensating device.

Axial thrust related problems are usually related to one or more of the following:

- High residual, unbalanced axial thrust with resultant excessive thrust bearing load

- Cyclic or transient rotor axial excursions or shuttling

- Failure of the thrust compensating disc (on machines equipped with one)

Symptoms of high axial thrust can include high bearing temperature and/or premature thrust bearing failure. High axial thrust may appear gradually as the internal pump clearances open up from wear, or may show up suddenly such as when the pump is throttled back in flow. Rotor axial shuttling may occur with reduced flow or minimum flow operation and can result in elevated pump vibration, especially in the axial direction, leading to failure of the thrust disc or thrust bearing.

On machines equipped with a thrust disc, which in theory is self-compensating over the range of residual axial thrust forces, failure of the device itself sometimes occurs. Thrust disc failure is usually associated with system transients, sudden reduction in suction pressure, vapor entrainment or possibly insufficient backpressure at the disc. The backup thrust bearing can withstand momentary excursions of the rotor, but cannot overcome failure of the thrust disc. Notwithstanding the fact that some self-compensating thrust disc devices are inherently more resistant to failure than others, Standard API 610 for the oil and gas industries disallows them altogether. Thrust disc failure will very likely cause immediate overload and failure of the backup thrust bearing and is more or less catastrophic to the machine.

Fortunately, axial thrust problems are relatively uncommon. But it is helpful to have a general understanding of the topic should such a problem occur.

For an independent evaluation of a pump axial thrust issue, contact an experienced consulting engineer who can help with your specific application.

Randal,

Which chapter is this statement referenced? Notwithstanding the fact that some self-compensating thrust disc devices are inherently more resistant to failure than others, Standard API 610 for the oil and gas industries disallows them altogether.

Russell,

Looking at a copy of API 610 10th Edition – I know this is not the most current version – under section 5.7 Wear rings and running clearances, paragraph 5.7.1 states “Radial running clearances shall be used to limit internal leakage and, where necessary, balance axial thrust. Impeller pumping vanes or close axial clearances shall not be used to balance axial thrust. …”

A thrust disc has a close axial clearance, and so would not be allowed. The common alternative is to use a compensating “drum” which is not self-compensating, but can be sized to limit the magnitude of the axial thrust.

I hope this answers your question.

Randal

[…] article was also published in Empowering Pumps, the new global resource for pump professionals. Randal is a featured Industry Pro on […]