Author: Jack Creamer, Schneider Electric

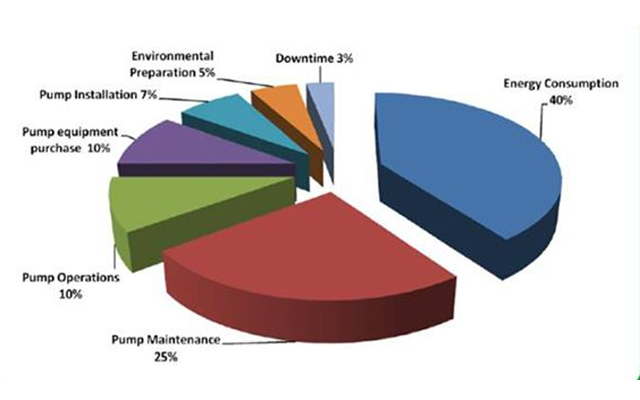

Pump stations are the greatest source of untapped savings for wastewater utilities. Forty percent of pump station costs are related to the energy required to move sewage. Another 38% is related to operations, maintenance, and downtime (see pie chart above). Yet many of the energy-saving technologies — particularly variable-frequency drives (VFDs) — that utilities have deployed to lower treatment costs aren’t used in collection assets like lift stations.

Several factors may explain the past reluctance to incorporate VFDs into Lift Station designs. A good example being that they’re individually small, and thus, not a focal point for life-cycle improvements. There also exist misconceptions that using VFDs to improve efficiency will compromise reliability. VFDs were once considered to be expensive and difficult to maintain for outdoor applications, but fundamental VFD design has evolved.

Today they are smaller, simpler to maintain/repair, and better adapted for the outdoors. VFDs are now enclosed to protect against dust, humidity, biological contaminates, and chemical gases, such as hydrogen sulfide. A National Electrical Manufacturers Association (NEMA) 3R drive rated at 122° F, for example, pushes filtered air past heat sinks and conformal-coated power components and houses sensitive control electronics within a separate compartment.

Most recently, VFDs are becoming SMART! They have embedded intelligence such as anti-cavitation protection to ensure reduced downtime. They have embedded algorithms to estimate flow and gauge whether the pump is running within its preferred operating region (POR). When combined with remote telemetry and big data, these units provide key performance data that utility managers can use to lower lift station operational costs and extend asset life.

Other examples of VFD intelligence include:

• Compensation for oversized pumps

• Energy usage management

• Pump wear monitoring

• Protection for abnormal events, such as low suction, friction loss, cavitation, broken shaft, and phase imbalance.

VFDs achieve their full potential when they’re part of asset-management infrastructure that provides ongoing feedback on system performance. Smart technologies and big data play a large role in enhancing drive effectiveness. Some are built into the drive; others are provided through process controllers, instrumentation, telemetry, and data analytics.

For example, smart VFDs and process controllers can use algorithms to estimate flow and gauge whether a pump is operating within its POR. A discharge pressure transmitter and flowmeter may be required for measurement on some systems, but that can be accomplished with a direct-buried flowmeter that eliminates the expense of a large drywell or separate meter vault. Instrumentation would then be available to accurately calculate pump curves for condition management of assets.

Then, factory pump curves could be compared against pump performance. This comparison could be used to calculate the energy wasted by under-performing pumps and the associated costs of not repairing the unit versus continued operation. This information is invaluable for the effective management of a collection system.

Smart technologies can be employed collectively at a lift station to address and enhance several Cost of Ownership factors, including maintenance and energy consumption, which accounts for close to 75% of the Total Cost of Ownership. It’s time to step up and embrace key tools, such as VFDs, to enhance Lift Station lifetime performance!

Comments