Author: Chett Norton, C.E.T., QA & Engineering Manager, & Gasket Guru at Triangle Fluid Controls

Many plants use steam for heating in addition to their standard processes, and with both fuel and water costs rising on an annual basis, just a small leak should not be taken lightly. This got me thinking, what is the ‘actual’ cost of correct gasket installation. Below is my short definition of a correct gasket installation:

1. Choosing the correct gasket material for the application (refer to Gasket Material Selection Tool).

2. Obtaining the recommended torque values from the material manufacturer.

3. Using a properly accredited bolt tightening procedure (refer to ASME PCC-1).

4. Wear the proper PPE.

What might a Steam Leak Cost?

To help paint a picture, I would like to use a familiar scenario. For this scenario, we have two pipe fitters: Bob and Joe. Both employees work at similar companies in town with the exact same amount of experience and training. Bob places a high degree of importance on the installation of gaskets in his plant, whereas Joe prides himself on how fast he can install the gasket and move on to the next task. Below is a side by side comparison of Bob and Joe’s installation of each gasket in the same application in a single bolted flange connection and the associated costs over a short, 12-day period.

The Cost of a Correct Gasket Installation

|

||

Day |

Bob | Joe |

1 |

Proper installation Time (25 min.) |

Improper installation Time (10 min.) |

2 |

No leak detected. | A leak is visually detected within 12 hrs of installation (needs tightening). |

10 |

No leak detected. | A leak is detected again but this time it is more severe than the last (needs tightening). |

12 |

No leak detected. | Gasket has ruptured due to overtightening, steam is pouring out (replace gasket). |

Analysis

|

1 Gasket:$ 8.65 Labour: $12.50 Lost Steam:$ 0.00 Total Cost: $21.15 – Actual cost per day: $1.76 and declining with each day that passes. |

2 Gaskets: $17.30 Labour: $26.15 Lost Steam: $12.10 Total Cost: $55.55 Actual cost per day: $4.63 and increasing with each day that passes if the installer continues to use the same gasket installation methods. |

Based on this scenario, here are a few things to consider: Proper gasket installation is initially more time consuming but it improves your return on investment (ROI) – increasing operating profit by reducing overall downtime and gasket inventory requirements. This analysis is based on one 3” 150# bolted flange joint. Just think about how many bolted joints are in an average industrial facility, and just how many of these bolted joints leak on average.

Small Steam Leak = Big Cost

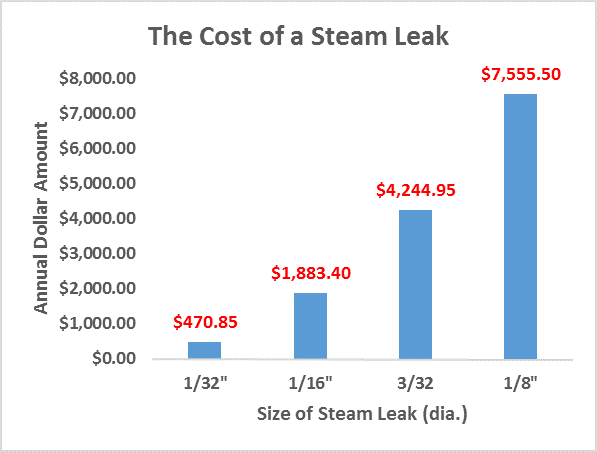

To help illustrate the costs associated with steam leaks, I have put together a bar graph using a steam loss calculator from American Plaint Maintenance, found at www.apmnortheast.com. The graph shows the average cost of a steam leak based on the diameter of the leak.

Now just imagine the above costs associated with 5, 10 or even 25 leaking bolted joint assemblies in your plant. Pretty scary thought, isn’t it?

Now just imagine the above costs associated with 5, 10 or even 25 leaking bolted joint assemblies in your plant. Pretty scary thought, isn’t it?

Negative Impacts of Gasket Leaks

Finally, the most important part of installing a gasket correctly is the safety factor. I mean, what if the final failure occurred during the last retightening sequence? Joe could have been seriously burned which could have resulted in a loss time incident, heavy fines or even a lawsuit. Let’s not forget that there are also environmental considerations which failing to comply with could introduce hefty fines, negative media attention or even remediation. So regardless of how quickly you can get the gasket installed, for the small amount of time saved, is it truly worth the probable outcome of a gasket failure in the end?

Remember to check back in near future for upcoming discussions on gasket installation procedures. ‘Till then, remember to be smart, be like Bob, and keep the fluid between the pipes!

http://test.empoweringpumps.com/white-papers/triangle-fluid-controls-gasketing-bolt-tightening-worksheet/

![Durlon Chemap® filters solve filtration tasks in a simpleand economic way [Case Study]](https://test.empoweringpumps.com/wp-content/uploads/2022/12/Durlon-Chemap®-filters-solve-filtration-tasks-in-a-simpleand-economic-way-Case-Study-7-380x199.png)

Comments