Greater Choice of Materials Enhances Capability and Versatility

A choice of diaphragm, check valve, and liquid end materials enables Hydra-Cell Metering Solutions pumps to operate over a wider range of processing applications than conventional metering pumps. In addition, special materials such as PVDF and Hastelloy C are available in standard Hydra-Cell packages.

Hydra-Cell is lower in cost compared to conventional metering pumps that have substantial price adders for exotic liquid end materials.

Manifolds

Manifolds

Manifolds for Hydra-Cell Metering Solutions pumps are available in metallic and non-metallic materials to suit your process application. They are easy to replace and interchangeable to accommodate different fluids processed by the same pump. Special manifolds are also available that offer 2:1 ratio pumping or the simultaneous pumping of three dissimilar fluids. (Consult factory.)

Valves

Valves

Hydra-Cell Metering Solutions valve assemblies (seats, valves, springs, and retainers) are available in a variety of materials to suit your process application.

Diaphragms and O-rings

Diaphragms and O-rings

Conventional metering pumps typically offer only PTFE diaphragms. When subjected to flex stresses, PTFE diaphragms do not have a “memory” like elastomeric diaphragms and will require more frequent and costly replacement due to stresses on the material. In addition, if fluid and process temperatures are low, and the PTFE diaphragm is cold, it can stiffen and cause irregularities in the output and a drop in flow.

Hydra-Cell offers PTFE diaphragms, as well as many other elastomeric material choices that may be more cost-effective or better suited to the application.

- Aflas

- EPDM

- FKM

- Neoprene

- Buna-N

Registered trademarks of materials:

Aflas® Asahi Glass Co., Ltd.

Buna®-N (Nitrile) E.I. Du Pont de Nemours and Company, Inc.

Celcon® Celanese Company

Elgiloy® Elgiloy Limited Partnership

Hapalon® (CSM) DuPont Dow Elastomers

Hastelloy® C Haynes International, Inc.

Kynar® (PVDF) Arkema, Inc.

Mesamoll® Lanxess Deutschland GmbH

Neoprene® E.I. Du Pont de Nemours and Company, Inc.

Nitronic® 50 AK Steel Corporation

Teflon® (PTFE) E.I. Du Pont de Nemours and Company, Inc.

Viton® (FKM) DuPont Performance Elastomers, LLC

Zytel® (Nylon) E.I. Du Pont de Nemours and Company, Inc.

Achieve Economy through Technology

Conventional metering pumps use technology in existence or unimproved upon for many years. This poses limitations such as inaccurate stroke adjusters, pulsation problems, restricted choice of materials, narrow adjustable flow ranges, and different plunger and diaphragm sizes. In addition, large footprints may be needed to handle high flows and pressures. Other pumps can also have difficulty handling slurries and suspended solids. Conventional metering pumps result in higher costs of acquisition, maintenance, and replacement. Hydra-Cell combines simple, elegant engineering with rugged construction to offer greater versatility while lowering life cycle costs. Design advantages include:

- Seal-less design means no mechanical or dynamic seals, cups, or packing to leak or replace.

- Smaller footprint that offers the same capability as larger, typically higher-priced pumps.

- Each model covers an extensive range of pressures and flows, whereas ordinary metering pumps may need different plunger and liquid end sizes to accommodate increases.

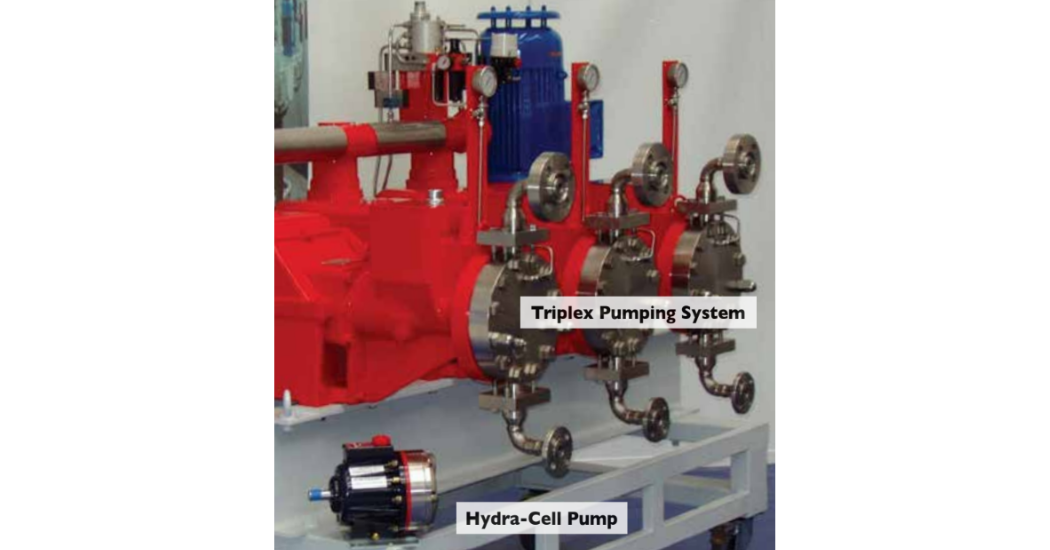

Both the Hydra-Cell pump and triplex metering pump shown have the same flow capacity and pressure rating. Hydra-Cell has a much smaller footprint, however, saving valuable floor space in your facility. Drastically smaller footprint equates to less expensive maintenance and reduced costs of spares. Conventional metering pumps can become over-sized and overpriced as flow and pressure requirements increase.

Ratings

Flow: 396 gph (1500 lph)

Pressure: 1160 psi (80 bar)

- The inherent simplicity of the Hydra-Cell design allows versatile application compared to complex metering pumps that require expensive construction changes to meet specific needs.

- Simplicity also means lower parts and maintenance costs.

- A separate gearbox allows greater versatility in changing applications and prevents cross-contamination of actuating oil; integral gearing on other pumps is difficult and expensive to change.

- A replenishment valve in every piston assembly ensures optimum actuating oil on every stroke for continuous accuracy – other metering pumps can leak oil past the plunger and may not be able to compensate on every stroke.

Comments