Paper mills consume many different chemicals to make paper. From bleached white, high-gloss paper to Kraft papers made from recycled products, all paper production utilizes chemicals.

Amorphous Silica, or Silicon Dioxide (SD), is a common component of paper. It improves fiber, fines, and starch retention for a smooth finish to the paper surface as the moisture is pressed out. SD is an aqueous colloidal solution. The raw silica is not fully dissolved in the water and can be difficult for pumps to meter accurately.

Pump Model: M03EKSGSNEMA x 3

Flow Rate: 0.3 to 2 gpm (1.7 to 7.5 l/min) per pump

Pressure: up to 150 psi (10 bar)

Application: Dosing Silicon Dioxide at a paper mill

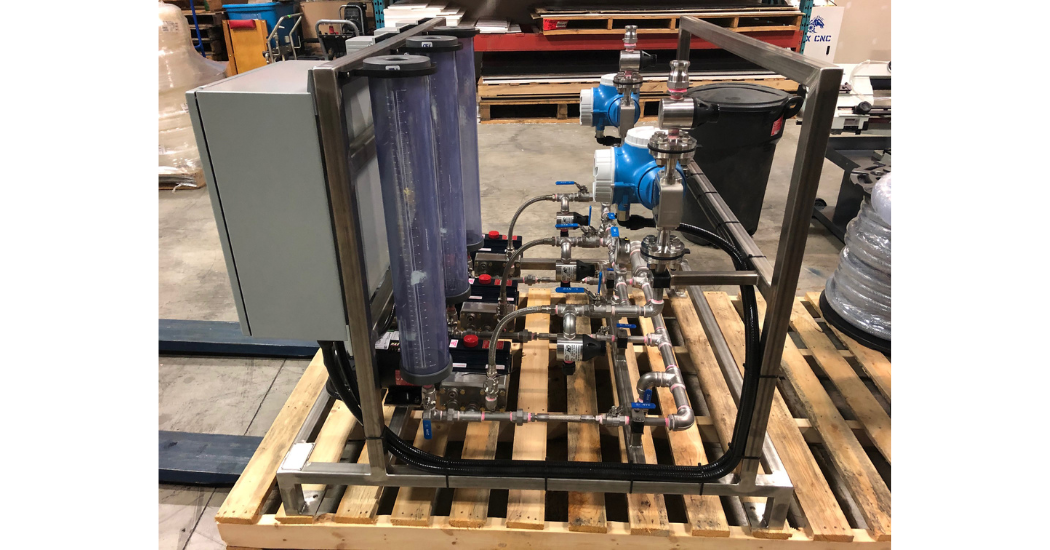

A mill installed a custom skid of three Hydra-Cell M03/G13 pumps that provide short stroke, triplex delivery to maintain velocity through the pump head and prevent undissolved solids from settling out. This is converse to many single-acting, competitive metering pumps.

The custom package includes a 316L Stainless Steel pressure relief valve and a 2000 mL calibration cylinder for each pump. With multiple Hydra-Cell pumps on one skid, the system can provide an extended range of flow as pump output increases through VFD control. This duplicity almost assures no unwanted downtime.

Comments