A meat processing plant used a piston/plunger pump to clean conveyors, tables, machinery, and other equipment. The demand to accommodate multiple showers with the necessary increase in pressure caused mechanical seal and packing failures. This resulted in significant downtime and maintenance costs that delayed the sanitation process.

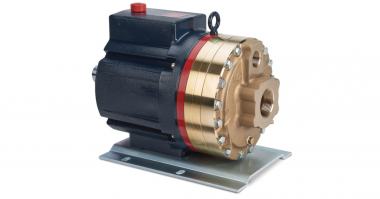

Pump Model: D35EKBTHFECE

Flow Rate: 34 gpm (128.7 l/min)

Pressure: 700-to-800 psi (48-to-55 bar)

Application: High-pressure sanitizing of meat

processing equipment

The processor replaced the piston/plunger pump with two Hydra-Cell D35/G35 seal-less pumps. With no seals or packing to wear or replace, the Hydra-Cell pumps have decreased service time and maintenance costs. Although one D35/G35 was intended as a backup, the two pumps work in unison when there is high demand. Operating with 30 hp motors, the Hydra-Cell pumps also meet the flow-pressure requirements with greater energy efficiency, delivering additional cost savings.

Comments