A major integrated petrochemicals company processes hydrocarbons into plastics, rubber, and other high-value products for state-of-the-art technological solutions. In one application, the injection of Monoethanolamide (MEA) strips out acid gases generated by the presence of Hydrogen Sulfide (H2S) and Carbon Dioxide (CO2). This process is often referred to as CO2 scrubbing.

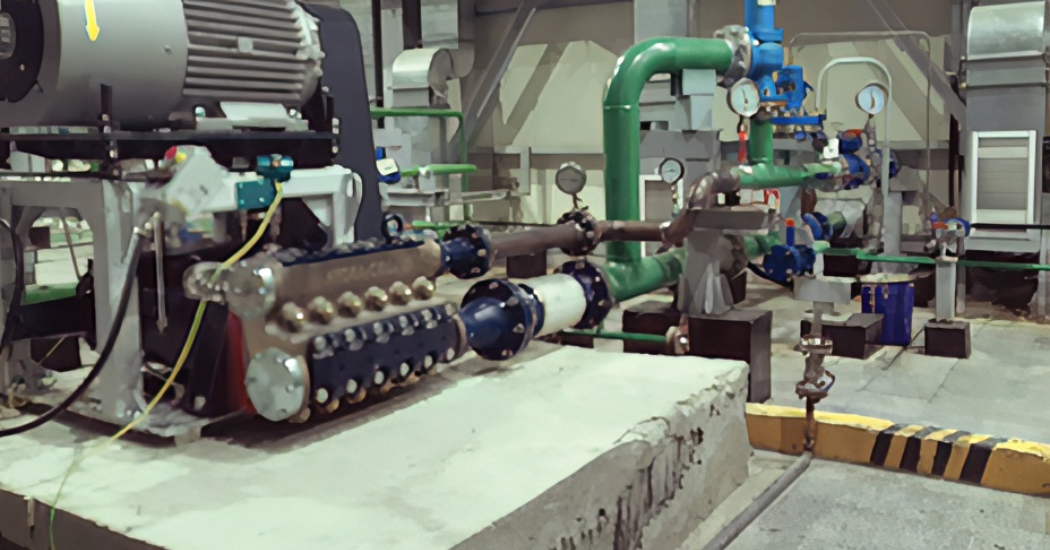

The plunger pumps in use leaked the process fluid through their dynamic, mechanical seals. The manufacturer already had two Hydra-Cell D35/G35 seal-less pumps running at the same duty and understood the reliability and value of using Hydra-Cell to handle hazardous liquids.

Pump Model: Q155ECDTHFESAX (4X)

Flow Rates: up to 92 gal/min (420 l/min)

Pressures: up to 870 psi (60 bar)

Application: Monoethanolamide at 3% concentration

in water injection

To achieve its flow requirements for injecting MEA, the company installed four Hydra-Cell Q155 seal-less pumps. Other reasons for selecting Hydra-Cell included:

- 100% leak-free operation to ensure operator safety and environmental responsibility.

- No dynamic seals to leak, wear or replace.

- Reliable handling of non-lubricating and low-viscosity liquids.

- Minimal maintenance and service requirements–no unplanned downtime.

Comments