PROJECT OVERVIEW

Waukesha Bearings Corporation’s engineered fluid film bearing production expanded to include magnetic bearings in 2001. The acquisition of Glacier RPB introduced Waukesha Magnetic Bearings (WMB) to the market. With the technological

advancements made over the past 10 years, active magnetic bearing reliability and availability levels have surpassed oil bearings when properly implemented. These advances have made an impact on the industry, drawing attention from major OEMs globally.

In 2002, a leading oil & gas customer approached WMB with the challenge of developing a bearing for a hermetically sealed integral motor compressor. Availability and reliability were the customer’s primary objectives. The end user could achieve a significant cap-ex savings in the installation if the motor compressor could be located outdoors, with no building or enclosure required. The sealed characteristic of the bearings and electrical connectors did indeed eliminate the requirement for a costly enclosure for the motor compressor and the end user realized a significant project cap-ex savings. The site-operating license placed limits on hydrocarbon emissions from the plant and the hermetic sealing of the bearings and motor compressor ensured the emission limits were not exceeded. Having created an integral motor compressor with greater availability and reliability, the customer delivered and installed its machine in 2006, outdoors, with no building or enclosure.

In 2002, a leading oil & gas customer approached WMB with the challenge of developing a bearing for a hermetically sealed integral motor compressor. Availability and reliability were the customer’s primary objectives. The end user could achieve a significant cap-ex savings in the installation if the motor compressor could be located outdoors, with no building or enclosure required. The sealed characteristic of the bearings and electrical connectors did indeed eliminate the requirement for a costly enclosure for the motor compressor and the end user realized a significant project cap-ex savings. The site-operating license placed limits on hydrocarbon emissions from the plant and the hermetic sealing of the bearings and motor compressor ensured the emission limits were not exceeded. Having created an integral motor compressor with greater availability and reliability, the customer delivered and installed its machine in 2006, outdoors, with no building or enclosure.

SOLVING THE CHALLENGE

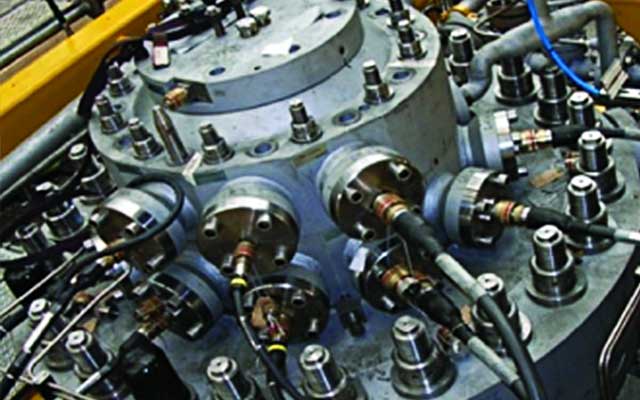

Magnetic bearings were the ideal solution for this application because they could be immersed in process gas. WMB’s experts engineered a canned magnetic bearing with metallic lined stators to segregate the electrical connections and windings from the corrosive gas. Canned magnetic bearings and sensors require high corrosion resistant metal encasement; special alloys ensure that the bearings will not corrode thereby protecting the inside of the machine from serious degradation. With canned AMB designs, the metallic can separates the pressurized volume inside the machine from the cavity pressure and ambient pressure and provides the first level of protection against leakage to the exterior of the machine. Because the metallic can will see a differential pressure equal to the maximum internal pressure of the machine, this component is required to withstand the maximum pressure inside the machine. A proper design of the metallic can and backing system is hence crucial to survive all the temperature and pressure conditions the AMBs will encounter during operation. WMB have received positive feedback from the end user for its collaboration with the OEM on the integral motor compressor.

PERFORMANCE IS WHAT COUNTS

After its 2006 installation, not only did WMB meet the customer’s primary goals, but the system proved to operate safely in its environment. 25,000 hours later, the units’ operation provides 99.9% availability to its end user. In addition, WMB’s canned bearings temperature ratings reached 165°C, compared to 130°C for competitor’s canned bearings.

A key advantage of canned magnetic bearings and corrosion resistant auxiliary bearings is the ability to be immersed in the process gas. Canned bearings allow for the placement of the magnet core and windings behind a pressure rated, impervious barrier constructed of corrosion resistant alloy (e.g. inconel) or other non-metallic material that is not susceptible to chemical attack by the process gas and condensates. Thus, electrical components are not exposed to the process conditions. This allows the motor compressor to eliminate the use of dry gas seals, avoiding natural and sour gas damage to the environment.

The figure shown has been adapted from NACE Standard MRO175 and is used to circumscribe regions of increasing corrosivity of sour process gas to metal alloys used in the construction of many components in use in the oil & gas industry. Corrosivity is defined by reference to SSC, sulfide stress cracking. The figure plots in situ pH against the partial pressure of hydrogen sulfide to signify increasing corrosivity from Regions 0 (no effect) to 3 and beyond (highest propensity for SSC). Magnetic bearings are being deployed in applications in the ability with the right design to immerse bearings directly in the process gas with all of the simplifications in design that entails.

This figure also displays the regimes where WMB’s, based on documented corrosion rates and other factors, has determined that sealed and canned designs may be applied while still expecting a reasonable service life. The dividing line corresponds to a concentration of about 600 ppm of chlorides.

The placement of the rotor system as described above inside a pressure vessel also has implications for cooling of motor and bearings, along with provisions for electrical connections penetrating the pressure vessel. Waukesha Magnetic Bearings has proven solutions for these and other design considerations.

VERSATILITY

It is important to consider the risks of erosion and corrosion with the potential for costly damage to the machine internals. Increasing regulation begs for environmental consideration in the oil and gas industry, giving canned bearing and corrosion-resistant auxiliary bearings a priceless benefit. Waukesha Magnetic Bearings can be applied in the manufacturing of integral motor compressors, in addition to other machines, such as conventional, externally driven compressors as well as turboexpanders.

For more information, visit the Waukesha Bearings’ website.

Comments