Background

An oil platform in the UK North Sea, which has been in operation since 1977, needed to improve the output of one of its oil wells.

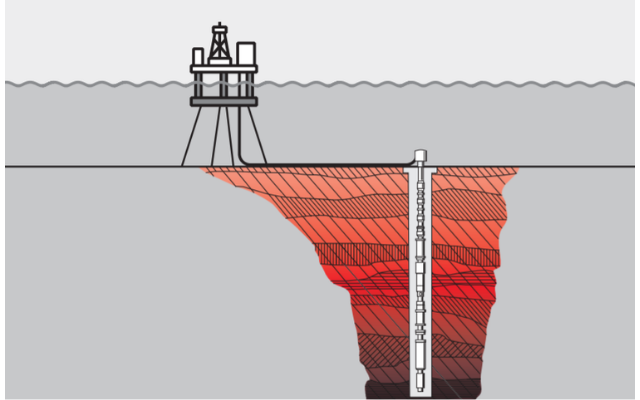

It was decided that an ESP (Electrical Submersible Pump) was required to provide some assistance or artificial lift to pump the well fluids to the platform.

ESPs

In wells where there is insufficient natural flow the pump and motor assembly are installed in the oil well to help lift fluids to the surface.

A variable speed drive is used to provide a controlled startup of the ESP and to adjust the ESP operating point (speed) to suit the well characteristics, which change over time. The use of a fixed speed motor would require frequent ESP change outs to match the changing well conditions.

Challenge

A 630 kW (836 hp), 4,140 V, 123 A ESP, including pump, motor and seal, was installed in the oil well at a depth of around 2,600 meters (8,530 ft). The unique installation included a dual ESP assembly to provide redundant pumping systems in this high intervention cost application. A variable speed drive was required on the platform to control and optimize the operation of the ESP.

Solution

Centrilift, ABB’s global ESP partner, was awarded a contract to supply the ESP system and associated offshore control module. The self-contained module was built with all the services required to power one ESP, but was designed to accept all the equipment required for a second ESP.

The ABB ACS1000 variable speed drive has been further developed to meet the requirements of ESP applications. The ACS1000 includes ESP specific hardware modifications, along with enhanced software control and protection functions required for ESP applications.

The ABB ACS1000 variable speed drive has been further developed to meet the requirements of ESP applications. The ACS1000 includes ESP specific hardware modifications, along with enhanced software control and protection functions required for ESP applications.

The design of the module required minimizing the amount of offshore interconnections. Additionally, the complete module, including ACS 1000 drive, step down input transformer, 13.8 kV switchgear and associated equipment, had to be kept below the 20 metric tons maximum lift capacity of the platform crane.

Benefits

Reduced operating cost

The cost of installing and removing an ESP in an oil well is an important factor in favor of variable speed drives. Some offshore operators typically quote US$ 1 million as the cost of changing an ESP, excluding the cost of the ESP itself. This figure includes the cost of a drilling rig required to install and remove an ESP, personnel cost, offshore transportation, etc. It does not include the loss of production incurred while the well is being worked over.

Minimized production loss

An ESP well workover typically takes around 10 -14 days. For a well producing 10,000 barrels of oil per day at an oil price of US$ 50 per barrel, this equals US$ 5 -7 million of lost or deferred production. Keeping the ESP in the well for as long as possible, and having the ability to adjust the ESP operating characteristics with a variable speed drive to suit the changing well conditions, is an extremely important factor in maximizing production and revenues.

Early delivery

The initial schedule for the project was for delivery of the complete module in 24 weeks. However, changes in the offshore drilling program dictated that the module be completed earlier – in only 17 weeks. By working closely together, Centrilift and ABB delivered the ACS1000 drive and transformer to the module fabricator in Aberdeen, Scotland, to meet the 17 week delivery requirement. As a result, the delivery date and final commissioning date were achieved on schedule.

Centrilift

Centrilift, headquartered in Claremore, Oklahoma, USA, is a division of the oilfield service company Baker Hughes, a GE Company. Centrilift is a worldwide market leader in electrical submersible pumping systems and related surface controls technology.

Centrilift’s contract was to pre-engineer, engineer and project manage the complete ESP topside control module and associated equipment.

Comments