Aegis talks a lot about shaft grounding for motors on drives, to mitigate electrical bearing damage. It almost goes without saying that motors’ frames need to be grounded, too. Almost. In fact, poor frame grounding contributes to electrical bearing damage as well. This bears discussion. For a video presentation, see this excellent on-demand webinar.

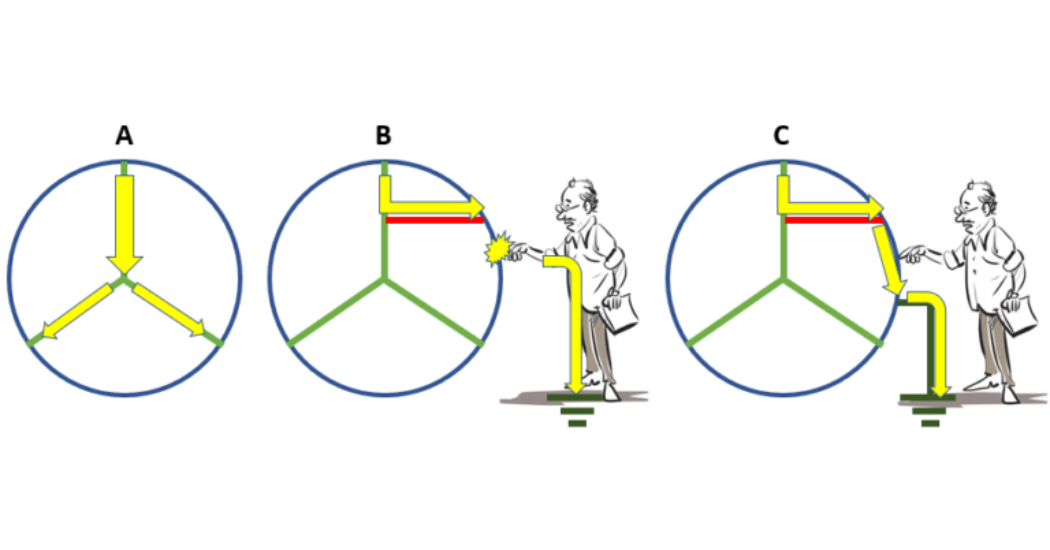

When a motor is run across the line, the voltage and current supplied to it are balanced. In a perfect world, all of the current flowing through the motor would always be in the three phase wires. Current would flow in through one phase, and return to the mains through the others. No grounding would be necessary. See A in the figure above. In the real world, the motor frame is grounded for safety reasons.

If an ungrounded frame was energized by a fault in one of the phases, it would create a lethal safety hazard. The motor might still run, but the frame would be “hot.” If someone touched the frame (B), their body would create an alternate path to ground (and back to the mains), and they would be shocked or electrocuted. Grounding the frame gives any stray current a safe low-resistance path to ground and back to the mains (C), mitigating the hazard. (The faulty motor would still need repair, but it would be much less likely to cause severe injury.)

A: Ungrounded motor with no faults. All current (yellow) enters and leaves the motor through the phase wires (green).

B: A fault (red) energizes the frame and creates a shock hazard. When touched, current runs from the frame, through the man, to ground.

C: With the frame grounded, stray current goes through the ground wire (dark green) instead of the man.

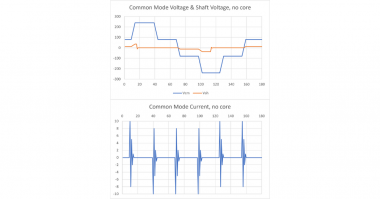

When a motor is powered by a drive, neither the voltage nor current is balanced. Drives’ output contains a lot of high-frequency (HF) noise. The frequency is important, because the motor windings have high impedance to HF currents. Consequently this noise will seek an alternate path back to the drive. When a drive’s output gets to a motor, the low frequency components of the current move through the phase windings, just like in a motor on line power.

But the HF current seeks an alternate route back to the drive. Rather than going through the stator windings, it moves (by capacitive coupling) onto the motor frame. From the motor frame, it will move back to the drive by every path it can find. If the motor is well-grounded, HF current will run to ground and then back to the drive. But if the motor is poorly grounded, it may arc through the bearings to the shaft, and seek ground through the coupled equipment. This is called rotor ground current, and it is the most destructive type of bearing current. It not only damages the motor bearings, but those of the driven equipment (pump, gearbox, etc.).

There are a few ways to avoid rotor ground current. Bonding the motor frame to the driven equipment gives stray current a lower-resistance path than going through the bearings. High frequency grounding straps, like the AEGIS® HFGS, work well for protecting motor and equipment bearings this way. Grounding straps are good for protecting bearings, but they’re not always enough. Bonding the motor and equipment frames still leaves the stray current free to meander through the facility grounding system on its way back to the drive. This can cause interference with or damage to sensitive equipment in the noise’s path.

Cross sections of high-end VFD cable. These examples include three symmetrically arranged ground wires and a conductive mesh sheath.

Cross sections of high-end VFD cable. These examples include three symmetrically arranged ground wires and a conductive mesh sheath.

In addition to motor-load bonding, you should bond the motor directly to the drive using proper VFD cable. There are many options for this, and drive manufacturers’ recommendations vary somewhat. ABB and Rockwell Automation have excellent booklets on grounding motors and drives. Variations aside, all good VFD cables include one or more ground conductors bonding the motor frame and the drive, and usually conductive mesh or foil shielding.

One more point: The cable’s shield must be properly terminated. If not, most of its benefits will be lost. See this blog post, or the guides linked above, for details.

With properly installed cable, up to 95% of the HF current moves directly from the motor frame back to the drive. Good cable thus protects the motor and equipment bearings from rotor ground current, and protects other sensitive equipment from stray noise current. We’ve only discussed conducted noise, but good cable minimizes radiated noise as well.

All of this said, rotor ground current is not the only source of electrical bearing damage. Proper cabling practices do not stop shaft voltage from building up and causing arcing through the bearings. So no matter how good the VFD cable, motors on drives still need reliable shaft grounding, like an AEGIS Shaft Grounding Ring.

AEGIS Rings come with a 2-year extended warranty against bearing fluting damage. No other form of protection against VFD-caused bearing damage offers a warranty like this.

To learn more about AEGIS shaft grounding and best practices for electrical bearing protection, sign up for a training. We offer monthly live training webinars, and – pandemic restrictions permitting – we can also visit your facility to review your exact application.

Comments