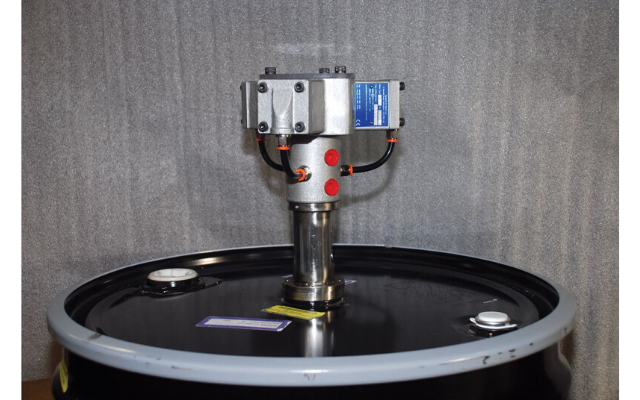

Providing robotic and automation systems for liquid paint spraying, Autoquip Inc. is a leading source of paint finishing equipment and services. Rather than industry-standard vane motors, Autoquip incorporates Huco Dynatork piston air motors into its systems. The air motor technology lends itself so well to the Autoquip’s proven flow control techniques.

As Autoquip’s Mike Elberson confirms, “By including the Huco Dynatork product, we can substantially reduce compressed air usage and ensure constant rpm of the agitator blade.” The result is a better surface finish and lower running costs. As Mike explains, “Historically a vane motor has been used as the means to agitate paint and keep solids in suspension. But one of the main drawbacks of this type of motor is that it has low torque at low rpm.” Based on 85% compressor efficiency the daily cost with a vane motor is $5.50 – $6.75. By including the Huco self-lubricating piston air motor, paint spraying systems cost just $.85 per day to run.

The agitation system is also far less cumbersome as the air motor naturally provides high torque at low speed, negating the need for a geared transmission. It is also much quieter in operation and, thanks to its dedicated controller, the air motor also ensures process consistency. Additionally, agitators often operate within an enclosed system where it is impossible to see the blade and determine the speed. Patented Huco Dynatork dual-mode airflow controllers are also utilized to provide more consistent speed regardless of mixing torque.

Highlights

Highlights

- Speed range: 150-700 rpm

- 87 in.lb. (9.8 Nm) torque at 200 RPM

- Unique free-floating piston design provides precise control

- Uses 80% less air compared to vane motors

- Corrosion-resistant housing

Comments