A major global industrial fan OEM needed a replacement coupling solution for an

induced draft fan drive at a large power plant. The fan maintains system pressure slightly

below atmospheric pressure on a coal-fired boiler at the facility. The existing fan drive used an old gear coupling design which had reached the end of its useful life.

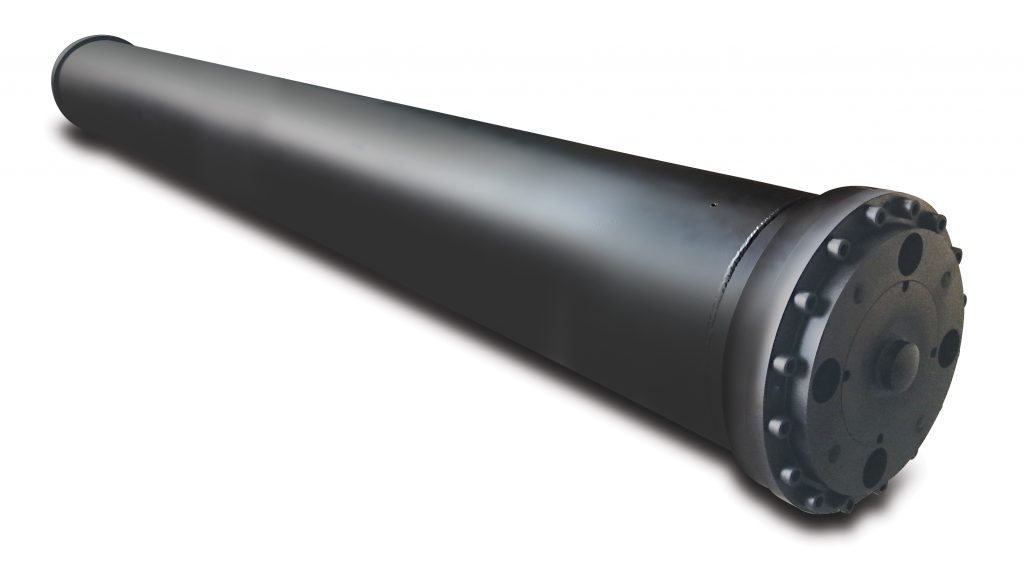

The OEM contacted TB Wood’s based on many previous successful collaborations. The

customer requested a disc coupling solution since they wanted to increase expected service life and eliminate the need for lubrication. TB Wood’s engineers recommended switching to a Form-Flex floating shaft coupling to mount between the drive motor and the fan.

The custom coupling was modified with limited end float features to keep the sleeve

bearing motor rotor from being damaged. The large 21.5 ft. long coupling is being used for an operating speed of 600 RPM, but the first critical speed is much higher due to the oversized tube diameter (24 in.) to meet the torsional requirements of the fan drive system.

The Form-Flex floating shaft has a continuous torque capacity of 1,100,000 lb.in. with a peak torque rating of 2,400,000 lb.in. The robust coupling design features an alloy steel motor hub with provisions for hydraulic removal, carbon steel flange adapter, welded steel spacer, high-strength alloy steel hardware and stainless steel disc packs.

The new coupling required a shaft hub connection at the motor end and a special adapter

flange on the fan end to mate with the existing fan flange. Since this was a retrofit

application, axial adjustment shims were provided so the customer could fine tune the

coupling spacing on the job site

Comments