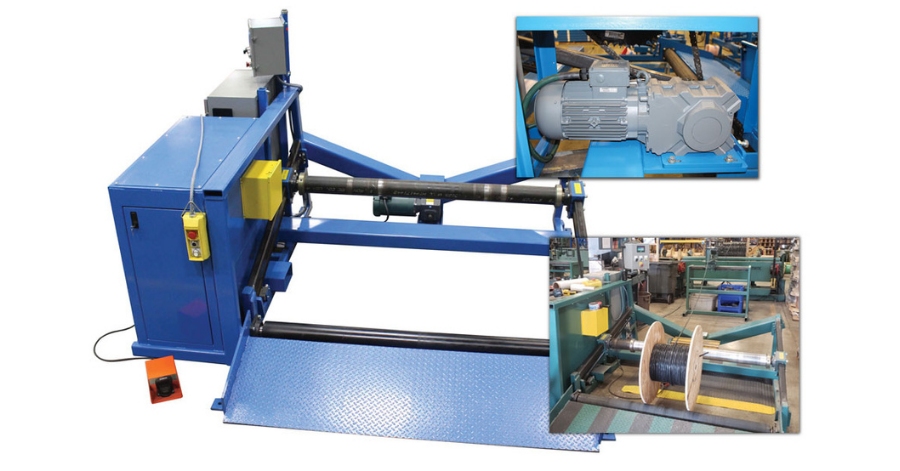

Reel Power Industrial, a leading manufacturer of reel and coiling solutions, needed space-saving, energy-efficient drives for a new rim drive take-up reel model. The equipment is typically used by wire and cable distribution facilities where large spools of copper wire are transferred down to smaller reels for contractor use. The machine uses a geared motor to drive a roller which rotates the cable reel as it coils. A smaller motor/gearbox drives two threaded rods which, in turn, move the ejection roller up and down the frame.

The new take-up reel was developed based on several factors, including customer demand for a smaller footprint. The only way to meet the reduced size requirement was to utilize a more power-dense right angle geared motor vs. the competitor in-line drive used on previous versions of the machine. The original 20 hp mechanical variable drive system was cumbersome and expensive to maintain. The OEM also wanted to take advantage of newer technologies by utilizing a more efficient unit.

After testing geared motors from different manufacturers, the OEM selected the Bauer BK Series unit for the main reel roller drivetrain. Bauer engineers worked closely with the OEM’s engineering team to fine-tune the motor to meet performance expectations. The compact Model BK40 supplied features a 15 hp PMSM (permanent magnet synchronous motor) that reduces heat losses from the rotor by 100% and total losses by approximately 25%, while increasing total efficiency by 10% or more. This improved performance translates into lower total cost of ownership, a reduction in CO2 emissions, and ongoing savings that buffer against future increases in energy costs.

A Boston Gear 700 Series speed reducer is utilized on the smaller ejection drive. The 700 Series is the industry standard for modular worm gear construction. Units feature a rugged fine grained cast iron housing for maximum strength and durability.

Highlights

Highlights

Bauer Gear Motor

BK Series Helical Bevel Geared Motor

With PMSM (permanent magnet synchronous motor) technology

Boston Gear

700 Series Speed Reducer

World-class worm gear technology provides quiet operation with efficiencies that can exceed 90%

Read about more Bauer Gear Motor solutions!

Comments