We’ve previously discussed ANSI process pumps and their role in performing functions to the guidelines set by the American National Standards Institute. In a similar fashion, API process pumps adhere to the standards set by American Petroleum Institute (API), more specifically the 610 standard for pumps in the petroleum, petrochemical, and natural gas industries. All API process pumps that meet the 610 standard are centrifugal, but they come in different forms and configurations based on their application.

What is the API Process Pump 610?

Now in its 11th edition, this standard applies to pumps running in reverse as hydraulic power recovery turbines that are not sealless pumps. The 610 makes recommendations for the most cost effective pump conditions. For example, it recommends pumps exceed discharge pressure of 1 900 kPa (275 psi; 19,0 bar), a rotative speed of 3 600 rpm, and pumping temperature of 150°C or 300°F.

For sealless API process pumps in the industry, there is the API 685, which makes similar recommendations. There is also the API 675 for controlled volume positive displacement pumps, API 677 for gear units, and API 682 for mechanical seals.

API Process Pump Applications

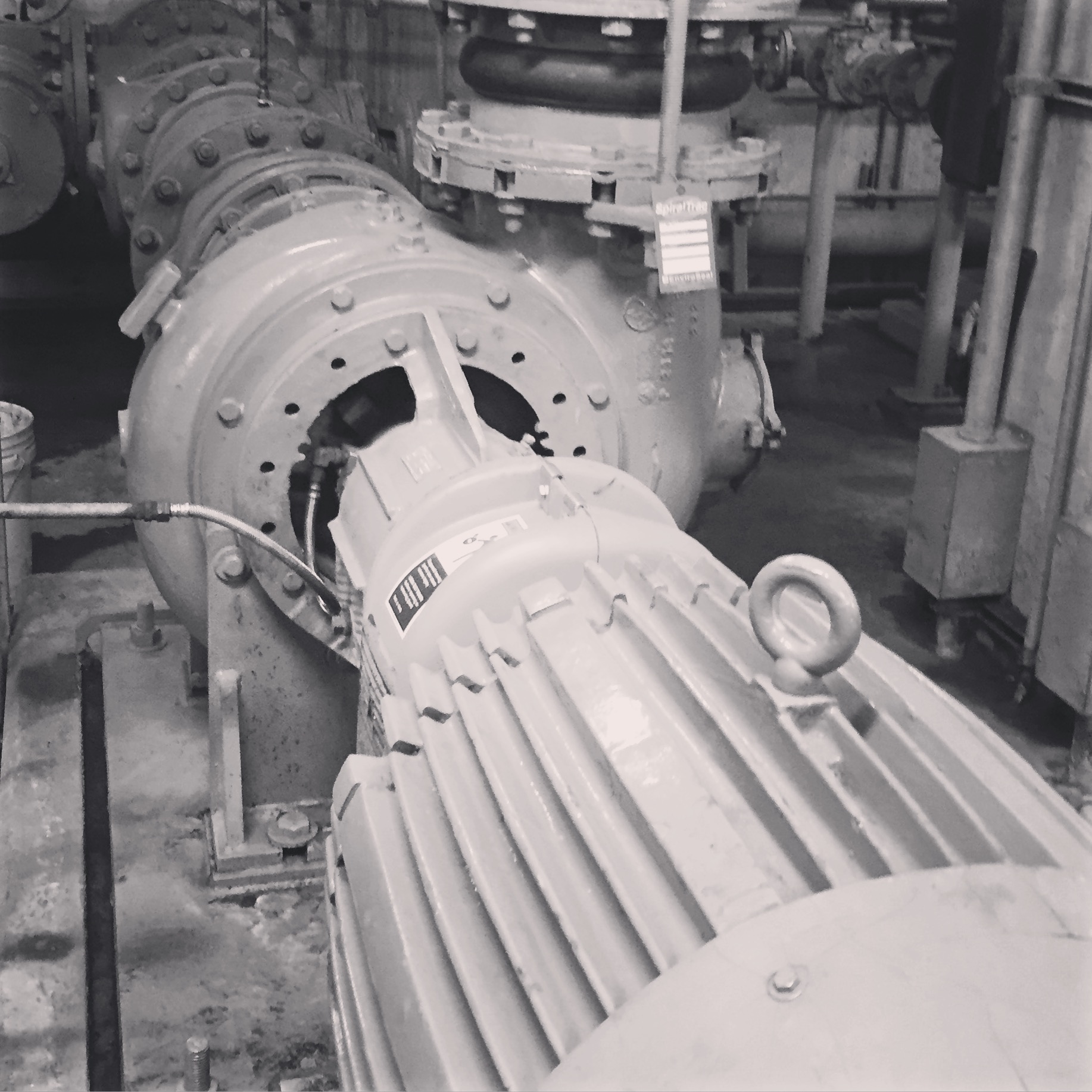

When most commonly used, the API process pump is an end suction centrifugal pump which is designed to work in high temperatures to move pressurized petroleum products. A primary feature of the pump is the support system at the centerline of the casing that acts to minimize the effects of thermal expansion. API process pumps can also be horizontal split case, vertical turbine, and any others used in the petroleum industry. The pumps are usually centerline mounted as a means to reduce thermal movement. They are also commonly operated with a closed impeller and locked wearing rings in order to move the liquid efficiently and minimize the chance of leakage. API process pumps are usually used to move crude oil and hydrocarbons.

API Process Pump Numbers

- Flow Rate Ranges – 10 – 10,000 gallons per minute, 38 – 37,854 liters per minute

- Total Head (Pressure) Ranges – 50 – 7,500 ft, 22 – 3251 psi

- Horse Power Ranges – 1 – 5,000 hp

Pro’s and Con’s of API Process Pumps

Just as the standard suggests, API pumps are ideal for the petrochemical industry because of the stringent standards they must adhere to. Given how expensive and dangerous hydrocarbons are when moved at high temperatures and pressures, the pumps are ideal for them. As a result, most API process pumps have superior allowable shaft deflection, bearing design, casing thickness, flanges, weldments, and so on.

API process pumps are not advisable in non-petroleum industries given their extra cost and maintenance. They are also not cost effective when moving liquids at low pressures or in large amounts. Although mostly used in oil production and pipelines, there are a few other sectors, such as the power industry, when a robust, conservative pump will do.

Advances in API Process Pumps

KSB Ecochem Non-Seal Pump –These pumps are leak-free canned and designed to transport hazardous, aggressive, flammable, and explosive fluids. The KSB pumps are also capable of handling volatile or valuable liquids, along with toxic and extremely hot or cold fluids. The pumps meet the requirements of the DIN/EN/ISO 15783 and API 685 standards and are economically operated via a new energy-optimized motor design.

HERMETIC CNP Canned Pumps These pumps utilize API 610 hydraulics and combine them with canned pump technology to provide a fully compliant API 685 sealless pump. They provide high levels of containment through an integral motor construction without the complex seal systems. This proven API solution helped name HERMETIC the best centrifugal pump manufacturer in January 2015.

For More on API Process Pumps

API Process Pumps vs ANSI Process Pumps – Want to know the main difference between the two without a lot of reading? Check out this free slideshow on Slideshare that makes a good case for both. It contains an article by Ross C. Mackay giving the pro’s and con’s of the two pumps.

Pump Markets – If you need to know the importance of pumps and how they play a role in many common industries, stop by this page from Europump. It features individual examples taken from existing utilities, including energy and API process pumps.

Standard: API Petroleum Process – Want to know more about the API standard? This guide lists all the basics, contains expert analysis and is available for individual purchase.

Comments