In this recent post from Applied Flow Technology, Dave Miller, Engineering Software Development Specialist, discusses Acceleration head, explaining that it “…is the energy required to change the velocity of the liquid in the system from an at rest, or zero condition, to some non-zero value.”

In this post, Miller uses a couple car analogies to explain acceleration head (excerpt below).

“The race car will accelerate to some maximum velocity, and then decelerate back to zero. The car does this by adding and removing energy using the engine and the brakes. Similarly, it takes energy to accelerate the liquid in a piping system. In another analogy, consider a car traveling across a city. In one case, the car is driven on an interstate highway at a constant speed. It takes a certain amount of energy to overcome the road and mechanical friction to maintain that constant speed. But if the car was driven on the city streets, having to stop and go at every stoplight along the way, the trip will take a lot more energy, and gasoline, due to the constant acceleration and deceleration of the vehicle.

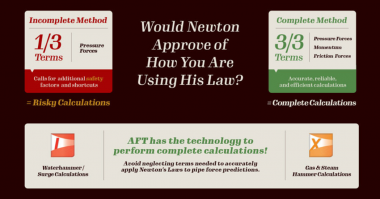

Traditional friction analysis of flows in pipes is based on constant, steady-state flows, as you would find in centrifugal pump flow. When starting a centrifugal pump, there is a peak power requirement that occurs due of the extra energy required to accelerate the liquid from a zero velocity to a steady-state flow velocity.

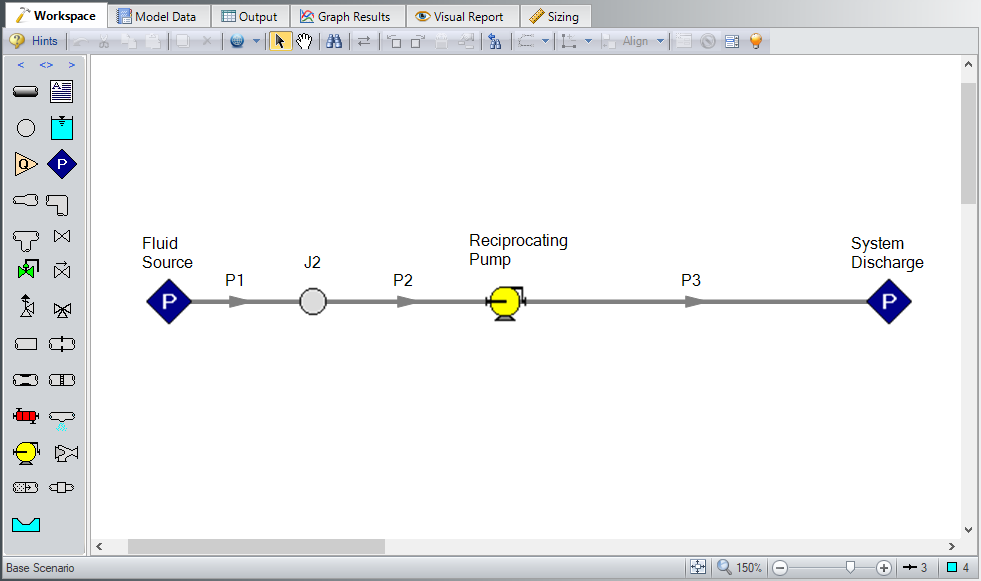

In the case of reciprocating pumps, the flow is not true steady-state flow, but is continually accelerating and decelerating. This continual change in fluid velocity requires more energy, or acceleration head, so traditional friction loss models may not be completely accurate when performing flow analysis.”

Comments