Chesterton, a leader in rotary sealing solutions for splash lubricated bearing protection, introduces a new non-contact Split Polymer Labyrinth Seal (SPLS) for large pumps, gearboxes, and other large rotating equipment.

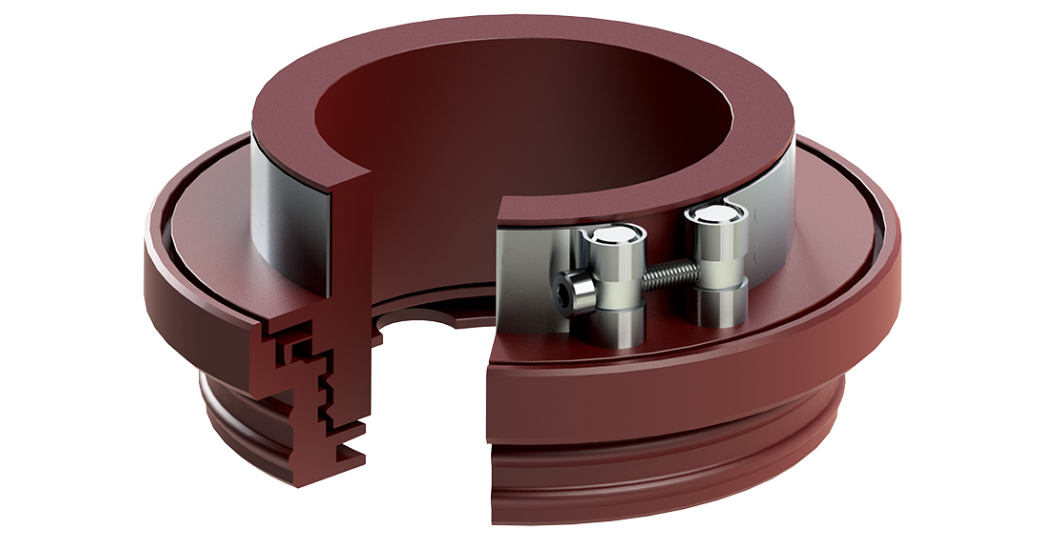

The SPLS uses Chesterton’s exclusive and industry-leading thermoset polyurethane to create a non-contacting 3-piece seal design that includes a rotor with a built-in split valve, a stator, and a metal clamp.

The SPLS can be installed with ease and reduces downtime associated with complex equipment disassembly. As tThe seal has practically no wearing components., The chances of fretting and wear of shafts typically seen in conventional lip seals are significantly minimized. The SPLS design serves the critical function of minimizing the ingress of external contaminants into gearboxes protecting critical rotary equipment.

This innovative product extends the life of equipment, improving mean time before failures (MTBF) and reducing maintenance costs. The SPLS is ideal for large gearboxes and horizontal split case pumps.

Comments