Chesterton, a leader in fluid sealing solutions and asset preservation, has released its latest pump packing innovation. DualPac® 2212 is a new non-staining, high-pressure packing that resists burning, extrusion and requires significantly fewer gland adjustments than conventional packing.

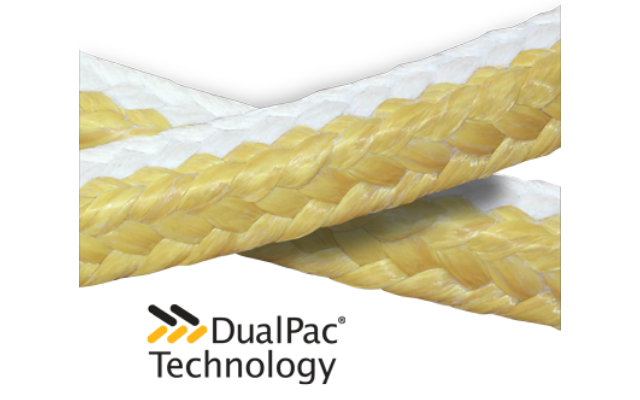

The Chesterton product is the second product release with DualPac braiding technology. DualPac 2212 combines a burn-resistant material (white) on the sealing side, with a highly resilient outer fiber (yellow). The burn-resistant material conforms to the pump shaft delivering a superior sealing performance, while the highly resilient fiber resists extrusion and transfers radial load to the sealing side of the packing. The result is a packing that utilizes the gland load more efficiently and achieves a reliable and quicker break-in period.

DualPac 2212 also provides exceptional sealing and extrusion resistance in one packing. Thanks to the DualPac braiding technology, it can be use as end-ring or seal-ring by simply reorienting the packing during installation, saving you time and money in your pump operation.

“DualPac 2212 is Chesterton’s next-generation product built on this unique technology to help customers achieve a longer packing life in highly demanding conditions,” says Raman Hanjra, Chesterton Director of Product Line Management for Packing and Gaskets. “Using it, they will benefit from lower energy costs and less overall maintenance compared to traditional packing.”

DualPac® 2212 is designed for demanding abrasive sealing applications in rotating equipment such as agitators, mixers, stock pumps, sludge pumps, slurry pumps, and process pumps.

Other pump sealing benefits of 2212 include:

- Better utilization of gland load helps minimize adjustments required

- Resists instant failure in the event of pressure surges

- Extends equipment life by reducing shaft or sleeve scoring

About A.W. Chesterton Company

Operating in over 100 countries around the world, Chesterton is recognized as a leading provider of knowledge backed solutions and expert service for Rotary, Stationary, and Fluid Power equipment supported by a comprehensive line of industrial fluid sealing solutions, high performance protective coatings, and specialty industrial lubrication.

Comments