A petrochemical company in Perm, Russia, was experiencing severe problems and high costs in maintaining the filtration/separator phase of their…

Operational costs (energy) and maintenance (service) account for more than 70% of a pump's total life cycle cost. As fluid…

The reasons you select a basket strainer instead of a Y-strainer are no longer valid. Independent testing shows the new…

Author: Bob Latino CEO at Reliability Center, Inc. This article is directed at those 'first responders' who arrive immediately at the failure…

Author: John Eblacker, Automation Specialist, WEG Electric Corp. Industrial Pump Sales & Service was contracted by the property management company of…

Author: Engineered Software Inc. 1. Improve the Quantity of the Pumped Product: A system simulation can be used to identify how…

Author: Bill Lenling, TST Coatings Protective coatings are a critical component in many pump designs. The coatings are used to provide surface…

When A Latin American Oil Company Optimized The Injection of Corrosion Inhibitors Into Its Pipelines, 500 Series Hydraulic Diaphragm Metering…

Author: Bob Latino CEO at Reliability Center, Inc. Abstract. In our last series highlighting the 4 primary Failure Modes (FM) of component failures…

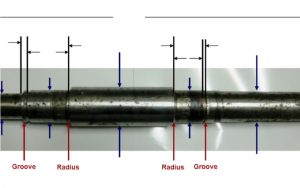

The main goal of static gasket materials used in flange assemblies is to assure the required level of tightness. In…

Author: Bob Latino CEO at Reliability Center, Inc. Note to Series Readers. To those following this Series, I will apologize for the front-end…