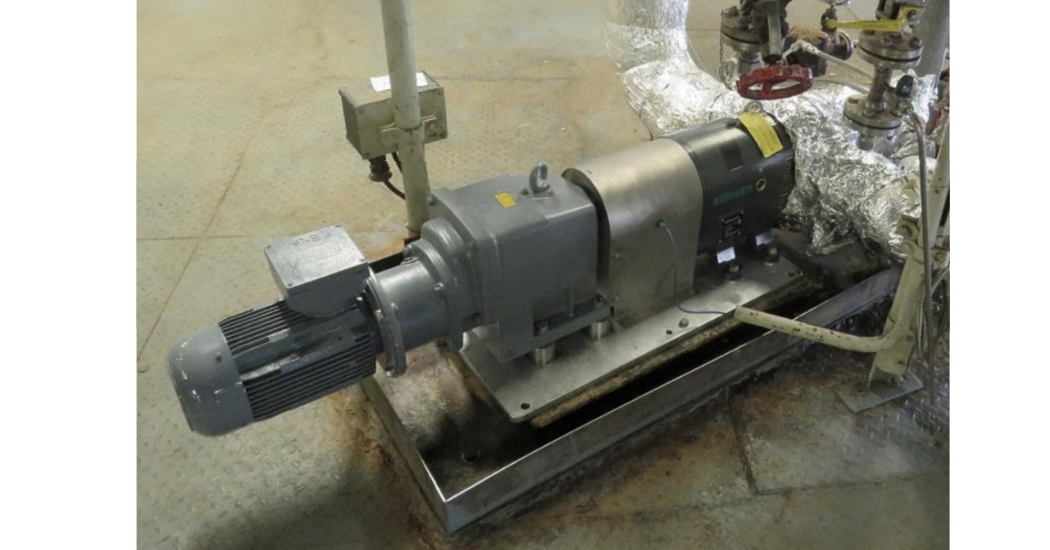

A manufacturer of plant protection products uses an ONIXline rotary lobe pump for conveying medium with a viscosity of up to 150,000 mPas. The pump made of duplex stainless steel sucks off the “melt” being formed in a thin-film evaporator and pumps it to a disperser. The rotary lobe pump used before from another manufacturer had persistent sealing problems. In addition, the maintenance work was very complex and cost-intensive. After an extensive market research, the chemical company opted for a Börger ONIXline rotary lobe pump. The customer was particularly impressed by the very robust and low-maintenance design as well as the option to integrate various sealing systems.

The pump has an ATEX-compliant design for use in potentially explosive atmospheres. The ONIXline is equipped with Börger double-acting mechanical seals as cartridge versions. The seals are pressurized. The stainless steel rotors with screw profile pump the highly viscous media with low pulsation and at a speed of 20 rpm. The medium has a temperature of up to 140 °C and must not cool down during the pumping process. For this reason, a heater cover is installed on the rotary lobe pump. The heater cover heats the pump chamber and thus ensuring a constantly high temperature of the medium.

The customer is very satisfied with the ONIXline rotary lobe pump. The pump creates a much higher vacuum than the pump used before which is why the customer can produce much more efficiently. The customer wants to use the ONIXline pump for other purposes as well.

Application data:

Pump type: Börger ONIXline BJ 090

Pumped medium: Melt in the production process of plant protection products

Viscosity: Up to 150,000 mPas

Temperature: Up to 140 °C

pH-value: Neutral

Flow rate: 0.7 m3/h

Speed: 20 rpm

Working pressure: 1.5 bar

Technical data:

Casing: Duplex stainless steel 1.4517

Casing protection plate: Stainless steel, 1.4539

Static O-rings: FFKM

Shaft seal: Double-acting Börger DA mechanical seal, pressurized

Rotors: Dual-lobe, screw profile, Primus, stainless steel 1.4539

Drive: Helical geared motor, Ex II 2G c/k T3, 1.85 kW

Advantages of this Börger ONIXline BJ 090

- Heated pump chamber due to pump heater cover

- Pumping of highly viscous media

- Self-priming

- High degree of operational safety due to Börger double-acting mechanical seals

- Short-term dry-run capability

- ATEX-compliant according to II 2G cbk IIB 200°C

- Ease of maintenance with MIP (Maintenance in Place)

Comments