Swing check valves are by far the most common check valve in any industry. They are often a lower-cost solution and effective most of the time; however, it’s important to understand the differences between a swing check valve and a spring check valve. Don’t get confused! In this article, we’ll cover some basic differences between these two types of inline check valves as well as some of the advantages of using a spring check valve over a swing check valve.

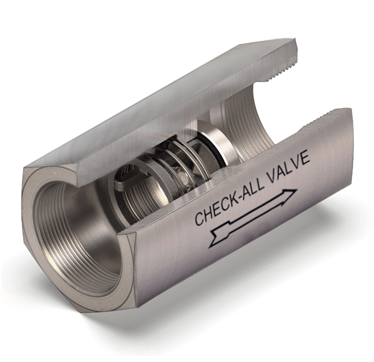

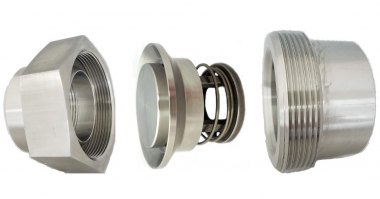

- The difference between swing check valves and spring check valves. The flapper in a swing check valve ‘swings’ off the seat to allow forward flow and then swings back onto the seat when the flow is stopped. In contrast, a spring loaded check valve incorporates a spring to assist in closing the check valve.

Learn more about spring check valves!

- Swing check valves are limited in the orientation in which they can be installed. Swing check valves can only be installed in horizontal flow applications, which greatly limits the installation orientation. While swing check valves do offer a larger flow capacity (larger CV value assuming the valve is fully open), they do not always fit in existing piping configurations. On the other hand, spring loaded check valves can be mounted in any flow orientation with the right spring selections. So if you have a skid system, difficult space with challenging dimensions, or even unique direction of piping, choosing a spring check valve with the right spring setting (a.k.a spring cracking pressure) creates more possibilities for finding the right solution for your specific pumping system.

- A spring loaded check valve will help minimize effects of water hammer, while a swing check valve can exacerbate the issue. Any water hammering effects present in a piping system can potentially be amplified by a swing check valve. Let’s consider this basic example to explain the concept of water hammer: say you have a line with water in it and you have a check valve. Downstream of that check valve, you have a quarter turn ball valve (this is one of the most commonly used types of control valves used for smaller line sizes). Let’s say water is flowing and someone shuts the quarter turn ball valve abruptly. This can produce a pressure wave flowing through the piping – this is what is known as water hammer. With a swing check valve specifically, the flapper on that valve will be open until that pressure wave returns back to the swing check. The pressure wave causes the flapper to slam shut, which is very much audible, and causes excessive wear within the swing check valve and other piping system components. Conversely, a spring loaded check valve will help minimize, and in some cases, eliminate the effects of water hammer. How? When we think about that same pressure wave that closed the swing check valve, the spring in the spring check closes before the pressure wave gets there. Spring check valves are considered “silent check valves” by utilizing a spring to assist the poppet in closing the check valve prior to fluid flow reversal.

We hope this clears up any confusion you may have around the differences between swing check valves and spring check valves and that you learned the advantages offered by spring check valves. All the valves Check-All Valve manufactures are inline spring loaded piston/poppet style check valves and we can answer any questions you may have. Use the comments to post your questions or tag us on social media. Stay tuned for our next article!

Comments