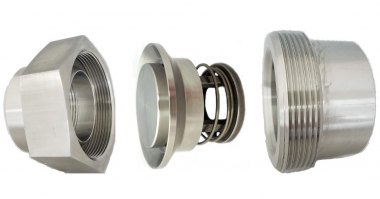

A vacuum insert valve goes into an ISO KFQF style flange. Normally these types of flanges have a centering ring with an outer O-ring that seals the flange together with a clamp-on top. Check-All Valve has integrated a check valve into the centering ring. For these types of flanges, the biggest benefit is that you can place a check valve literally anywhere you have a flange. You are simply replacing the centering ring with a centering ring that has a check valve.

With zero takeout, vacuum insert valves can be placed anywhere. They are perfect for retrofits or new builds because removing any of the piping system to incorporate the valve into the system itself is not required.

Vacuum insert valves are generally used for niche applications in the pharmaceutical, medical, or food and beverage industries—in applications where high purity is required.

The Top 10 Benefits of Vacuum Insert Valves

- Vacuum insert valves have zero takeout. When you are designing a piping system, or if you

are maintaining a piping system and you need to incorporate a new piping system component,

the last thing you want to have to do is cut tubing, weld something, or thread something. With this valve there is literally zero takeout. It can easily be placed into an existing system. - There are many different build options. Normally vacuum insert valves are offered in stainless steel because that is generally the material used for the piping. However, Check-All Valve offers many different types of seat materials.

- There is a broad variety of spring cracking pressures. Standard cracking pressures start as specific as 0.125 psi and go up incrementally from there.

- Check-All Valve vacuum insert valves utilize a standard trim design. The technology is well proven. Check-All Valve is not reinventing the wheel for how a valve operates, it is just a different style of convention than what has previously been offered.

- Vacuum insert valves are cost-competitive.

- They are readily available with short lead times. It takes generally 3-to-5 days to assemble, but because there are so many options sometimes it takes a week to two weeks to deliver, depending on the destination. There are some options that can be expedited on the same day.

- In the sanitary check valve industry, if there are 3-to-6 inches of takeout, the guts can be removed, and the vacuum insert valve can be used on the downstream side without the need for re-piping.

- They can be used anywhere there is a joint in the piping system.

- The compact design requires no additional space in the line. Its size makes it extremely economical when compared to full-bodied valves.

- The vacuum insert valve can also be used as a low-pressure relief valve under either positive or vacuum conditions by using the desired spring setting.

Comments