Designed to close prior to fluid flow reversal, a spring loaded check valve incorporates a spring to assist in closing the check valve. This is important because preventing backflow eliminates the hydraulic shock that is also known as water hammer (a result of the sudden fluid stoppage of flow in a fluid process system).

Check valves protect both the suction and discharge sides of pumps, in addition to preventing backflow of possibly contaminated water.

Spring-loaded check valves are perfect for protecting equipment from backflow damage, but they also provide pressure relief for system safety. In addition, they prevent contamination from reverse flow and no human intervention is required for them to function. Spring-loaded check valves are powered by flow and differential pressure with assistance from the pressure of the swing.

The commonality of at check valve should not hide the importance of its function. Check valves are installed to protect piping systems, equipment, and public health. Improperly installed check valves can result in costly repairs and system shutdowns.

A very common installation of a spring-loaded check valve is at a pump. It may be installed on the suction side of the pump to maintain the pump’s prime in the event of a pump shutdown. A check valve will be used commonly on the discharge of the pump to prevent backflow from the downstream system, which can happen when the pump shuts off.

Spring-loaded check valves have many benefits:

- They provide quick interruption of flow.

- They provide positive sealing at pressures below the cracking pressure of the valve.

- They do not require gravity or backflow pressure to work or to actuate.

- They provide positive valve closure regardless of vertical orientation.

- They prevent system fluid or gas backflow during routine maintenance.

- Springs can accommodate very wide temperature ranges.

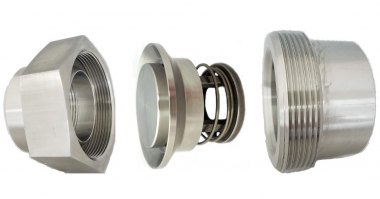

The function of a spring-loaded check valve is, easy to understand. When flow enters the input port of the valve, it has to have enough pressure (force) to overcome the cracking pressure and the spring force. Once overcome, it pushes the disc, opening the orifice and allowing flow to move through the valve.

When the input pressure is no longer high enough, or there is a backpressure, then the backpressure and spring push the disc against the orifice and seal the valve shut. The spring, along with the short travel distance for the disc, allows for quick reaction time for closing. This valve design also prevents against pressure surges in the line, and therefore, also prevents a water hammer from occurring. They can be installed in a vertical or horizontal orientation.

All valves Check-All manufactures are inline check valves. Check-All offers multiple seat materials and spring cracking pressures to meet all of your application needs. For more information, be sure to visit https://www.checkall.com/spring-loaded-check-valve/ today.

Comments