When unwanted air develops in a closed vessel or pipeline, vacuum breakers provide a simple, dependable way to relieve it. A vacuum breaker allows air to enter a system to replace a change in volume that may occur during the stream-to-condensate phase change. They can be used to prevent contamination from backflowing in fluid handling systems and protect equipment against collapse or implosion.

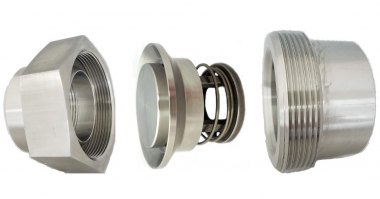

It’s a simple concept. The vacuum breaker will not allow air to escape from the pipeline. When the pressure in the barrel—which naturally wants to suck in outside air because of the cooling—is enough to overpower the spring, the check mechanism moves in with the spring and allows the outside air into the barrel. This prevents the implosion of the barrel. There are different spring tensions for different strengths of vessels.

Vacuum breakers provide tight enclosures with tension response, provide large air venting capacity, and are designed for easy installation and long service life. An optional air release valve can be piped to the side of the valve to release trapped air during pipeline operation—slowly exhausting the air that was admitted into the pipeline. The slow release of air prevents the sudden rejoining of separated columns in a pipeline and the associated pressure surges, or water hammer.

The vacuum breaker seals against positive pressure keeping the check mechanism in the closed position. With a light spring cracking pressure (spring setting), the check mechanism will begin to open at very low vacuum conditions providing immediate protection. When positive pressure is restored in the pipe or tank, the valve will automatically close and seal tightly. The vacuum breaker is mounted at critical pipeline high points, penstocks, or tanks and allows for rapid inflow of atmospheric air to reduce vacuum conditions in piping systems.

In general, low-pressure relief valves (such as spring-loaded check valves) can serve dual roles as vacuum breakers. A tank is a common application where a check valve would be installed at the top of the piping to relieve the vacuum when the tank is being pumped down.

Another application where check valves can function as vacuum breakers is when there is a dramatic change in piping elevation. Vacuum relief valves can also be installed in vacuum systems in order to pull a specific amount of vacuum. There could be some thermal applications where the media can change from very hot temperatures to very cold temperatures, and the differences in volume between temperatures is an instance that may require a vacuum breaker to relieve that vacuum when it is created as a result of a variance in temperature.

Engineering check valves since 1958, Check-All® Mfg. Co. is an outstanding source for all your check valve, vacuum breaker, and low-pressure relief applications. For more information, please visit https://www.checkall.com/2020/08/26/what-is-a-check-valve-used-for/

Comments