Author: Juan Cid, Product Manager, A.W. Chesterton Company

Braided packing is the oldest pump sealing method used in the process and service industry. Packing has proven to be a reliable and cost-effective sealing choice, especially when pump shaft motion and misalignment issues are not suitable for mechanical seals or when leakage is not a major concern.

However, the reliability of conventional braided packing is highly dependent upon the sleeve and flush conditions:

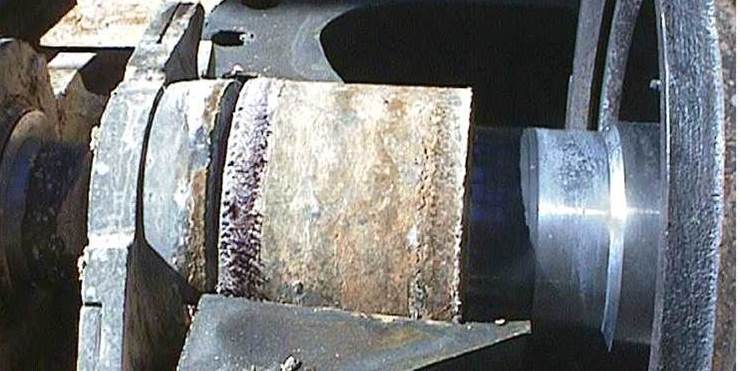

- Sleeve roughness and high spots can cause rapid wear of the packing.

- Flush solids embedded between the packing and the shaft can increase pump sleeve damage, causing unplanned equipment downtime and additional expense.

Maintenance and repair costs of a worn sleeve, as well as flush treatment, can be challenging and sometimes unfeasible. Unscheduled pump shutdowns and downtime can severely increase the cost of production. In addition, a clean flush is often unavailable or too expensive to maintain and remove from the diluted process product, making the packing failure unavoidable.

The Impact of Sealing Systems on the Energy Efficiency of Pumps [eBook]

New pump packing material technology provides alternatives to conventional braided packing that can better adapt to worn sleeves and contaminated flush.

Injectable packing is one of these technologies that has proven to be highly effective for worn equipment. Unlike braided or die formed packing, injectable packing is a hybrid between a solid and a liquid composed of chopped reinforced fiber mixed with lubricants. Injectable packing works, as the name implies, by injecting the packing through the lantern ring flush port into the stuffing box – Read the full article.

Comments