A.W. Chesterton Company, a global leader in fluid sealing, is pleased to announce the availability of its innovative Kaplan Runner Blade Trunnion Split Seal, which can help hydropower plants reduce costly turbine downtime and limit the release of operating fluid into the environment.

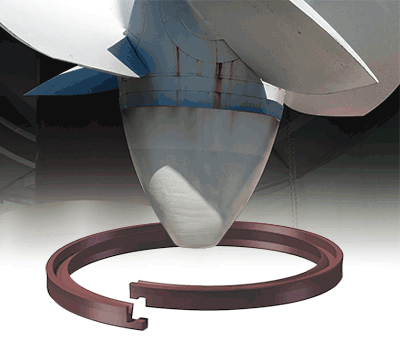

Chesterton® Kaplan Runner Blade Trunnion Split Seals are high-performance lip seals for heavy-duty, dynamic rotary and oscillating seal applications in the hydropower industry. These seals are specifically designed for the Kaplan (or “propeller type”) turbine runner blade trunnions.

The Runner Blade Trunnion Seal is just one of the fully array of Kaplan Turbine product solutions available from Chesterton.

Faster Installation & Increased Reliability

The seal’s split design reduces downtime by allowing for easy and fast installation. The removal of the blade is not required for installation and there is no need for complex welding, gluing, or post processing of the split joint. In addition, only two seals need to be installed in back-to-back configuration rather than a full stacked set. This configuration also keeps the hydraulic media and lubricant in the turbine hub, and protects the hub against ingress of water, solid particles and sediments

Maintains Load Pressure & Rotary Shaft Movement

The Chesterton Kaplan Runner Blade Trunnion Seal is designed with positive, flared dynamic lip design that resists the rotary motion that could pull the split apart and uses load pressure to join the cut ends. During blade positioning, Chesterton’s seal maintains load pressure and also allows for rotary shaft movement with minimal frictional drag.

Compensates for Blade Droop

A typical reliability issue with an older Kaplan Turbine is blade droop caused by worn trunnion bushings. The Chesterton trunnion seal design compensates by providing reliable sealing despite any droop.

Durable Seal Material Offers Longer Life in Hydropower Environment

This seal is made with Chesterton’s AWC800 (95 Shore A) high-performance thermoset polymer (EU) material, which offers excellent abrasion resistance and improved durability, and has a proven record of withstanding severe operating conditions. The polymer provides a built-in molybdenum disulfide lubricant to minimize frictional drag. Its superior memory enables the seal to automatically adjust and compensate for radial cross-sectional variances commonly associated with blade droop.

Direct Retrofit

The geometry and dimensions of the Kaplan Runner Blade Trunnion Seal are made-to-order according to actual hardware arrangement and dimensions.

About A.W. Chesterton Company

Operating in over 100 countries around the world, Chesterton is recognized as a leading provider of knowledge backed solutions and expert service for Rotary, Stationary, and Fluid Power equipment supported by a comprehensive line of industrial fluid sealing solutions, high performance protective coatings, and specialty industrial lubrication.

Comments