Boars Head Service Reservoir provides fresh drinking water to just under 6,000 customers across 3 DMA’s near Wigan, Lancashire. The site had been operating for a number of years using a 12″ (300mm) actuated butterfly valve to control the tank inlet water supply to control at a pre-determined minimum and maximum water level.

The site does not have accurate flow metering and so the valve operation was spindle % position only, the levels were controlled manually by a United Utilities operator continually adjusting the % position. This proved very challenging and time consuming, plus there is a second reservoir fed from the same system that Boars Head has an impact on balancing level.

The site also experienced a history of pressure transients due to rapid changes in flow velocity based by uncontrolled actuator movements. Due to limitations in valve design UU were struggling to control levels accurately and consistently and wanted to explore an automated and effective method of operation and provide a diurnal level control pattern whilst managing water turnover.

United Utilities approached Cla-Val to explore what solution could be sought. Listening to their issues Cla-Val was able to help, plus retain the use of the existing valve by installing the Cla-Val VC-22D Controller.

Onsite actuator motor assembly and VC-22D Controller

Reservoir Management

- No Flowmeter required

- Default position % on loss of level signal

- Network Calming approach Utilizes existing asset

- Removes pressure transients

- No water quality risks

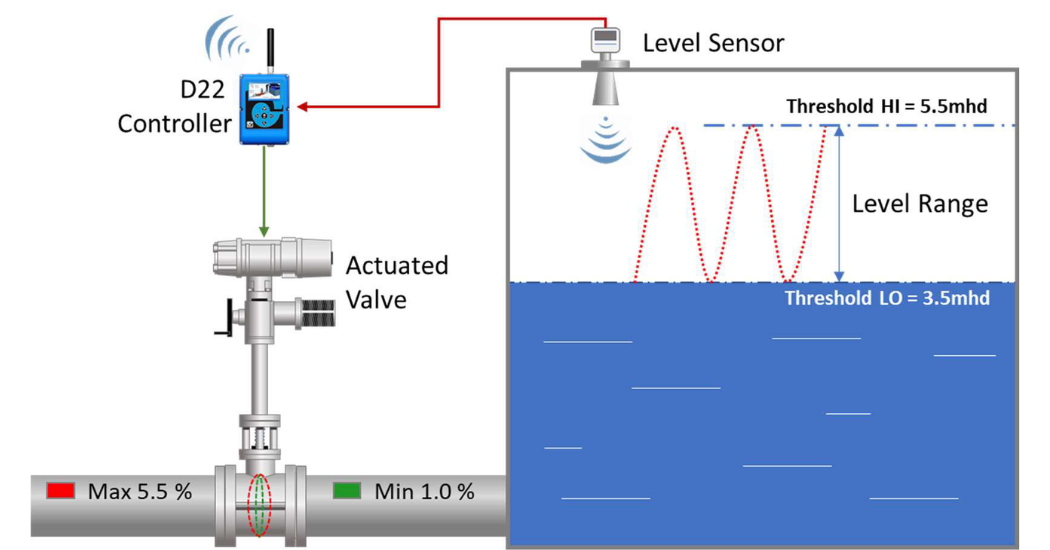

The VC-22D Controller provides site-specific Valvapps. In this application, Cla-Val used a ‘fill & drain Valvapp’ to automatically control levels between a pre-set range. By taking the 4-20mA reservoir level signal back to the VC-22D Cla-Val were able to program a minimum and maximum level threshold (between 11.48 ft (3.5m)hd and 18 ft (5.5m)hd) and create two % values to output to the valve actuator to facilitate filling and draining of the tank (1% to drain and 5.5% to fill).

By using the VC-22D Controller were able to offer a complete solution.

- Remove transient behavior – by ramping actuator % to ensure open and close action was slow and smooth (1% per minute)

- Provide a diurnal level pattern across a 7-day period by utilizing preprogrammed fill and drain %

- Provide water turnover – level HI and LO thresholds

- Drives actuator to default % on level signal failure

Comments