The SS Badger provides the largest cross-lake ferry service on the Great Lakes. The 410-foot steamship travels the 60-mile span across Lake Michigan between Ludington, Michigan and Manitowoc, Wisconsin, in four hours – about half the time it takes to drive around Lake Michigan through Chicago. It serves both commercial and recreational customers, carrying freight, vehicles, and up to 600 passengers.

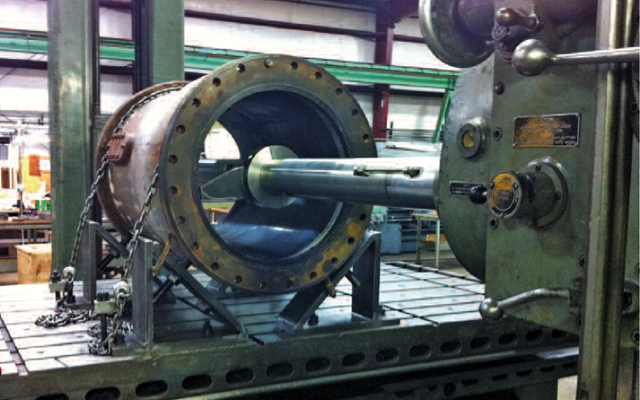

The Badger is the last coal-powered ferry operating on the Great Lakes. The unique propulsion system is driven by two Skinner Unaflow four-cylinder, reciprocating steam engines rated 3,500 horsepower at 125 rpm. Each engine decompresses steam to create the volume necessary to move pistons and make power.

The Badger is the last coal-powered ferry operating on the Great Lakes. The unique propulsion system is driven by two Skinner Unaflow four-cylinder, reciprocating steam engines rated 3,500 horsepower at 125 rpm. Each engine decompresses steam to create the volume necessary to move pistons and make power.

Worn cylinder liners were robbing the engine of power and frequent piston ring failures adding considerable expense and downtime. The vessel’s owner, Lake Michigan Carferry, contacted Cook Compression to help extend operating intervals and reduce maintenance costs. Lake Michigan Carferry turned to Cook because the two companies enjoyed a long-running relationship. Cook was the piston ring and seal ring OEM for the Skinner Steam Engine Company when the engines were built over half a century ago.

Specialists from Cook Compression assessed the application and developed a plan using the Cook Compression Service Center in La Porte (IN) to perform repairs and manufacture new parts. Cook engineered, manufactured and installed liners in all eight high-pressure cylinders(plus one spare), in addition to replacing piston rings in all associated cylinders.

Specialists from Cook Compression assessed the application and developed a plan using the Cook Compression Service Center in La Porte (IN) to perform repairs and manufacture new parts. Cook engineered, manufactured and installed liners in all eight high-pressure cylinders(plus one spare), in addition to replacing piston rings in all associated cylinders.

In the past, the Badger’s maintenance crew had to replace piston rings several times per operating season. Following the American Bureau of Shipping-certified Cook repair service – which included new engineered 4-piece piston rings, lubrication ports and cylinder liners – the Badger is now able to complete an entire season without incurring downtime due to failed power rings. After a season of operations, a company spokesman said they will see significant savings through future years of operation with more reliable service for their customers.

Comments