Making the right pump selection is very important; the right choice can reduce energy costs and provide decades of strong service. The wrong choice could dramatically increase operation and maintenance costs, and limit the life of the pump.

This reminder of what to check comes from Cornell Pump’s Hydraulic Seminar workbook. The information is a reminder of lessons about calculating Total Dynamic Head (TDH). Participants at Cornell’s Virtual Pump School 2020, will not only get this handy workbook, but also get numerous presentations (e.g. NPSH, TDH, pump sizing, etc.) that lead to this very topic (Pump Selection) being covered in detail on day three of the school. Plus, you’ll get the Condensed Hydraulic Databook, along with many other reference materials.

Right now, cost for general admission to the school is only $79 USD. But hurry – It goes up to $99 this weekend. Learn more about Virtual Pump School 2020. The school runs September 15 through 17, 2020, with ten sessions total offered per day; five each in Basic and Advanced tracks.

How To Select a Centrifugal Pump

The pump is selected after all the system data has been gathered and computed. The system TOTAL CAPACITY in gallons per minute and TOTAL DYNAMIC HEAD in feet must be determined. You should consider suction submergence, NPSHr and NPSHa, various speeds, other drives (engine, motor, etc.) and all system conditions to optimize the selection.

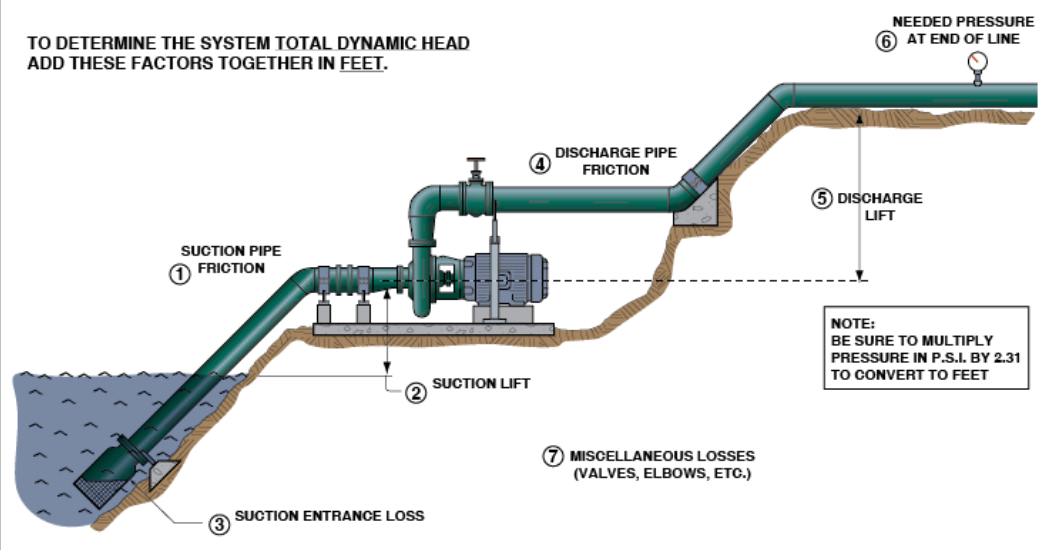

Typical Pump Installation

- TOTAL DYNAMIC HEAD is the SUM of the following:

- Suction pipe friction (see Condensed Hydraulic Data Book).

- Suction lift (vertical distance, in feet, from lowest expected water surface to center of pump inlet).

- Suction entrance loss (usually figured at one velocity head plus foot valve losses

- Discharge pipe friction (Condensed Hydraulic Data Book).

- Discharge lift (vertical distance, in feet from pump to high point in system).

- Pressure, in feet, for service intended (pressure, in P.S.I., x 2.31 equals feet of head).

- Miscellaneous losses, in feet (for valves, elbow, and all other fittings, see Condensed Hydraulic Data Book).

Example 1:

- For capacity of 320 GPM, total head in feet is determined as follows:

- 28’ Suction friction (6” steel pipe, 20’ long – 1.39’/c x 20’)

- 5’ Suction lift

- 3’ est. Suction entrance loss (1’ vel. Head + 0.49’ + screen loss)

- 14’ Discharge friction (6” steel pipe,1000’ long – 1.39’/c x 1000’)

- 15’ Discharge lift

- 100’ System pressure (43 P.S.I. x 2.31)

- 10’ Miscellaneous losses (Use your own safety factor here)

- 147’ total head (Approx.)

Example 2:

- For capacity of 600 GPM, total head in feet is determined as follows:

- .89’ Suction friction (6” steel pipe, 20’ long – 4.46’/c x 20’)

- 5’ Suction lift

- 5’ est. Suction entrance loss (1’ vel. Head + 1.6’ + screen loss)

- 45’ Discharge friction (6” steel pipe, 1000’ long, – 4.46’/c x 1000’)

- 15’ Discharge lift

- 100’ System pressure (43 PSI x 2.31)

- 15’ Miscellaneous losses (Use your own safety factor here)

- 186’ total head

Comments