KSB brings to the U.S. more than 140 years of global experience and competence of centrifugal pump technology that is designed for optimum reliability and maximized performance. KSB is backed by an established network of sales and service locations to meet customers‘ needs.

Quick solutions for spare parts

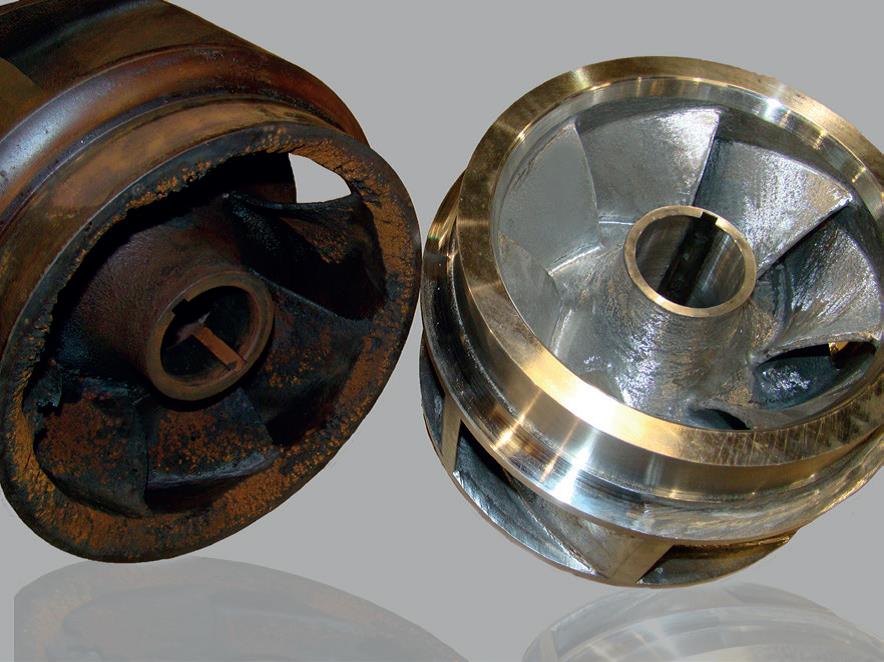

Breakdowns occur daily and customers are often faced with the difficult task of sourcing replacement parts that may not be available or have long delivery times. In such cases, KSB offers Reverse Engineering which is a process of rapid manufacturing that enables the production of high quality castings within a very short time frame. This solution allows you to keep your existing equipment in operation, avoid costly plant modifications. and production loss. Within the process KSB uses their own foundries and manufacturing facilities in the USA in order to streamline the process. The customer receives short delivery times for high quality individual parts such as impellers and diffusers or casings made of stainless steel, duplex, super-duplex or bronze and all kinds of special materials. We extend this technology beyond pumps to include all types of casted parts or prototypes produced by any manufacturer. Our expertise allows our customers to incorporate design changes and material upgrades in the process to improve the original components.

Our services

- 3D measurement and modeling

- Optimization of component design with regard to material, geometry and hydraulics

- Quality casting and machining

Customer Benefits

Whatever your needs, our reverse engineering services can be your solution:

- Short delivery times

- Longer life with optional optimization of design and higher quality materials

- High quality replicas – at least as good as the original

- Ensuring the life cycle of your equipment

- Increase of MTBF (Mean Time BetweenFailure)

Your local KSB office can provide further information on our reverse engineering technology and services.

Contacts:

East Coast

KSB, Inc. – sales@ksbusa.com

Southwest

Standard Alloys Inc. – sales@standardalloys.com

West Coast

Precision Pump & Machine – info@precisionpump.com

Comments