A fire can occur anywhere, anytime with no respect for rules or regulations. And the consequences for both humans and assets can be catastrophic.

No matter where the fire breaks out: onboard a ship, in a crowded building, offshore, or in essential infrastructure there is a great demand for a safe, efficient, and immediate activating firefighting system.

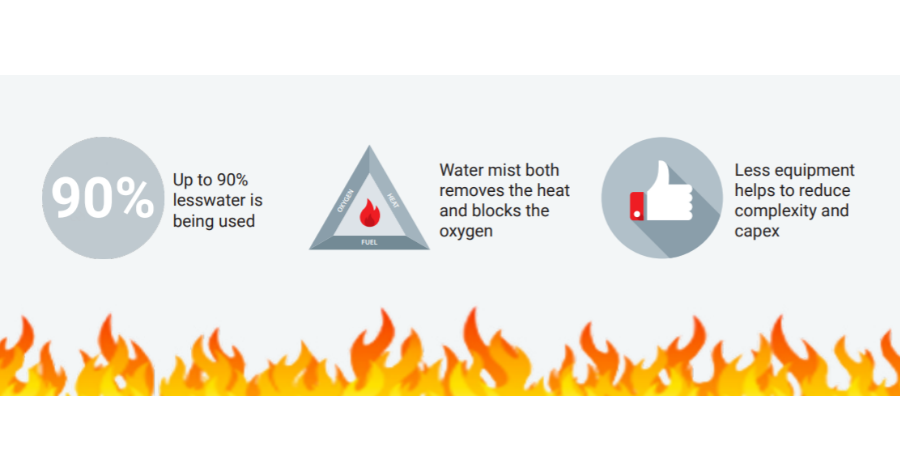

Using high-pressure water mist is one of the most effective ways to fight fires. And at the same time, the mist isn’t as devastating to the immediate surroundings and assets than tons of water spread by traditional sprinklers.

Water mist benefits

Danfoss components for firefighting water mist systems

Danfoss components for firefighting water mist systems

Danfoss offers high-pressure components for water mist systems that comply to the strictest quality standards. They are suitable for both commercial and industrial applications:

- High Reliability

- Low Maintenance

- High Efficiency

- Easy installation

We are committed to support our customers within the fire fighting industry.

Our high-pressure pumps, sectional valves, check valves and relief valves cover your needs when using high-pressure water mist.

- Less maintenance

- Unrivaled reliability

- Low complexity

- Easy installation

- Less maintenance

- Unrivaled reliability

- Easy installation

- Stainless steel to ensure high quality and reliability

VRH pressure relief valve

- Reliable and corrosion resistant

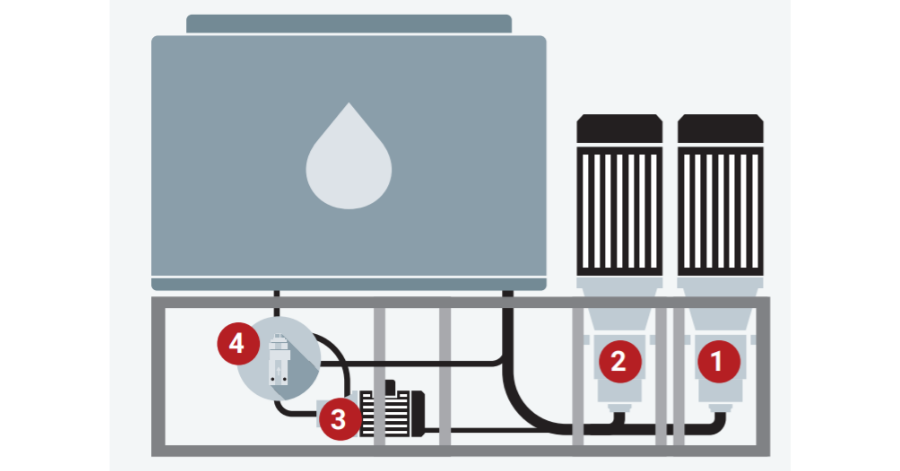

Danfoss components used in a high-pressure water mist system

- Main pump (PAH)

- Redundancy via extra pump (PAH)

- Jockey pump (PAH)

- Valves: Pressure relief valve (VRH), Check valve (VCH)

The high-pressure sectional valves (VDHT) are placed in the different zones e.g. on each floor in a high-rise building.

Comments