Cooling towers are integral components in a variety of industrial and manufacturing processes; electric power generation plants are one of the most common and recognizable applications.

Serving as heat-rejection devices, cooling towers transfer process-generated heat from a system into the atmosphere. Open- or closed-circuit water systems pick up heat throughout the system; in the tower itself, the lower temperature of the atmosphere cools the water, usually by allowing a degree of evaporation.

Cooling towers require very complex water — and, occasionally, steam — piping systems.

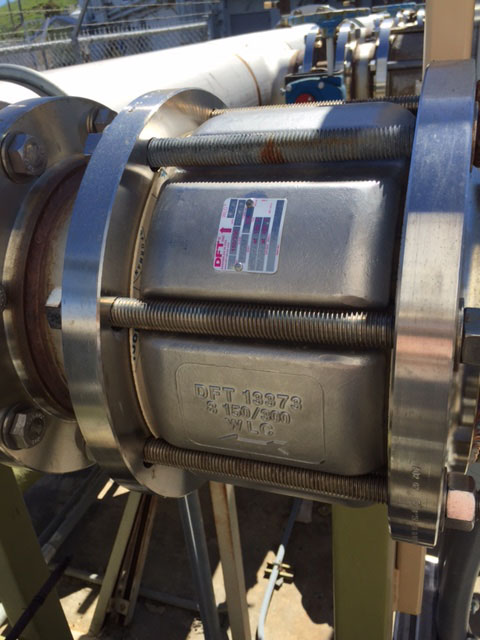

One of DFT®’s clients, based in California, has a number of functioning cooling towers. In 1993, this client replaced 24 check valves in the piping system of a cooling tower with axial flow check silent check valves from DFT®.

In the intervening 24 years, only one of those valves required replacement — in 2017. The remaining 23 DFT® check valves from 1993 remain in good working order, allowing this client significant cost savings.

Comments