Facility: Copper Mine in Arizona, United States of America

Application Problem: Solvent Extraction & Electrowinning – Mine Dewatering and Water Hammer

Solution: DFT® Model ALC® Wafer Check Valve, RF-Flanged GLC®, & Excalibur®

Success Since: 2015

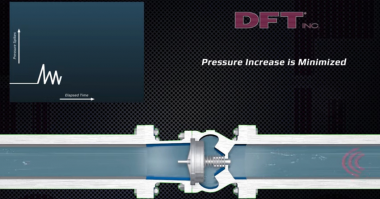

Challenge: An Arizona Copper Mine using SXEW (Solvent Extraction & Electrowinning ) was looking to prevent instances of reverse flow, water hammer and failing valves.

SXEW is a two-stage hydro metallurgical process that first extracts & upgrades copper ions from low grade leach solutions into a solvent containing a chemical that selectively reacts with and binds the copper in the solvent.

Additionally, options were being sought to reduce water hammer during Mine Dewatering which is the lowering of the water table near quarries, mines, or other extraction sites. Mine dewatering removes water using specialized pumps that are constantly in use.

This process optimizes mine production and stabilizes mine walls during extractions, and silent check valves help support the entire application, while also reducing or eliminating water hammer.

Solution: Several DFT® Silent Check Valves were chosen as solutions for use in Mine Dewatering and SXEW to prevent reverse flow and water hammer.

The long life and tight shutoff make them a popular choice, as the costs of “change outs” or failures is substantial.

DFT® Model ALC® Features:

DFT® Model ALC® Features:

- 2” to 24” line size

- ASME class 150 and 300

- RF wafer ends

- API 594 face-to-face dimensions

- Tight shutoff-lapped disc & seat

- Stainless steel seat, disc & bushing

- Horizontal or vertical installation

DFT® Model GLC® Features:

DFT® Model GLC® Features:

- 2” to 42” line size*

- ASME class 150 to 2500

- RF & RTJ flanged ends

- “Short” face-to-face dimensions

- Stainless steel trim

- Center-guided/dual-guided stem

- Spring assisted silent closing, non-slam

- Tight shutoff – lapped disc & seat

- Horizontal or vertical installation

DFT® Model Excalibur® Features:

DFT® Model Excalibur® Features:

- 2” to 24” line size*

- ASME class 150 to 1500

- RF & RTJ flanged ends, butt weld ends

- ASME B16.10 face-to-face dimensions

- Stainless steel trim

- Center-guided/dual-guided stem

- Spring assisted silent closing, non-slam

- Tight shutoff – lapped disc & seat

- Two-piece body

- Horizontal or vertical installation

*For larger sizes contact DFT

For more information on Industry success stories, click here.

Comments