A Large Natural Gas Company in West Virginia was experiencing issues with its piston check valves. They were installed at its compressor station located near the natural gas underground storage.

An important component of the natural gas transportation system is the compressor station. The stations are used to compress natural gas as it travels throughout the pipelines. It is this compression that allows the gas to continue to flow through the pipes to its final destination for distribution.

The Piston check valves at the compressor discharge cycled often, regulating the pressure of the underground storage. This high cycle application required the piston check valves to have yearly service performed on them and replacement parts were installed every other year.

Six of the 6” 900# WCB/SS DFT® model PDC® Check Valves were the right solution to replace the piston check valves originally installed for this application.

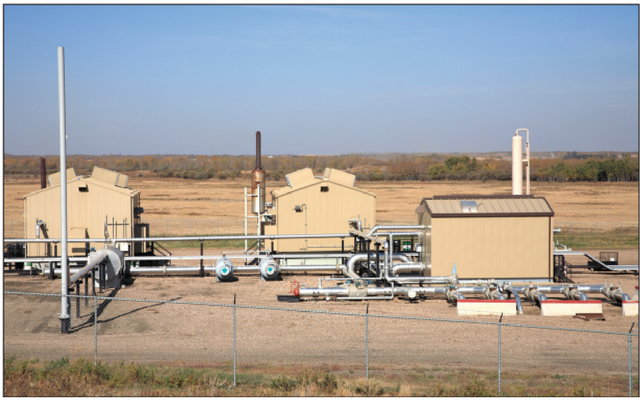

Design Layout: Compressor House with 6-6” 900# lines coming out 15 feet with gate valve/ PDC followed by 6 feet of pipe turn into the ground connecting into a 20” mainline underground.

The PDC’s provided the customer 13 years of maintenance free service. They were installed in 1999 and performed properly until 2012, when service was performed on the valves.

DFT® Model PDC®

DFT® Model PDC®

Features:

• 2” to 26” line size

• ASME class 150 to 1500

• RF & RTJ flanged ends

• ASME B16.10 face-to

face dimensions

• Standard Body Materials:

– A216 WCB carbon steel

– A351 CF8M stainless steel

– A352 LCC low-carbon

steel

• Stainless steel trim

• Center-guided/dual

guided stem

• Spring assisted silent

closing, non-slam

• Tight shutoff – lapped disc

& seat

• Horizontal or vertical installation

• Protected spring

• Axial Flow

• Nozzle style

Choose the Right Solution for Your application with Our Free eBook

Comments