Water hammer is a shockwave that moves through the fluid (liquid) contained in a piping system. This shockwave occurs when a fluid already in motion is suddenly stopped, ceasing to move through the pipe.

The abrupt stop creates a pressure surge that moves through the fluid, affecting everything within the closed pipe system. Though the pressure dissipates fairly quickly, the resulting damage can be long-lasting and widespread — potentially causing damage to various system parts and components, such as expansion joints, gasketed pipe joints, pressure sensors, flowmeters, and the pipe walls. This pressure commonly results in a thumping or banging noise akin to hammering, hence the term “water hammer.”

Though some degree of water hammer is inevitable in any type of piping system, leaving it unmitigated can result in serious system-wide issues, and even complete failure.

The Effects of Hydraulic Shock

The resulting shockwave — the increase in fluid pressure that occurs when a fluid’s movement through the pipe suddenly stops — is referred to as hydraulic shock. The most common cause of hydraulic shock is either a valve closing too quickly or a pump shutting down suddenly.

When a valve closes too quickly, the fluid after the valve will elastically stretch because of the momentum of that fluid until the fluid’s momentum stops. The fluid will then inevitably try to return to its normal, unstressed state — much like a stretched rubber band snaps back once released. This action, however, will also cause the fluid to travel back through the pipe. The fluid that flows back will hit the closed valve, sometimes with a very strong force, which can be extremely destructive.

Water hammer, also known as liquid hammer, is very common and can occur in both residential and industrial settings. In homes, any action involving water can trigger water hammer. This includes taking a shower, washing clothes, and running the dishwasher. In industrial settings, water hammer can be caused by improper valve selection, unsuitable valve locations (swing check valves in vertical pipe runs), and poor maintenance.

Choosing the Right Valves to Combat Water Hammer

The types of valves being used in a piping system can play a major role in whether or not water hammer occurs. For example, swing check valves — one of the oldest designs available — are the most commonly used style in piping systems. With these valves, the flow of the fluid opens the valve, and the fluid’s reverse flow closes it. But as popular as they are, these valves often result in water hammer since the opening and closing mechanisms have no way to control the pressure surge.

Tilting disc check valves are also commonly used in piping systems. These function in a similar way to swing check valves; the flowing fluid opens the valve, and when the flow reverses, the valve closes — sometimes resulting in water hammer.

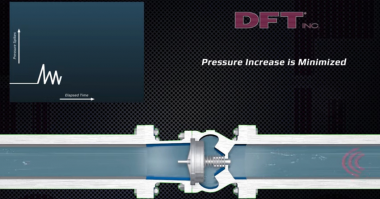

The use of silent (in-line) check valves, however, can help prevent the occurrence of water hammer. A relatively new style of check valve, these feature a unique design that allows the flow to open the valve, while internal springs help close the valve before the flow reverses — thereby reducing or even eliminating the occurrence of water hammer and its various effects. In-Line (Silent) Check Valves can be successfully installed in either vertical or horizontal pipe runs.

At DFT® Inc., we’re proud to help clients combat and, most importantly, prevent the various problems associated with check valves — including water hammer. We offer a wide selection of valves for various applications and environments, and supply silent (in-line) check valves to help reduce the risk of water hammer in various applications, keeping systems running smoothly and efficiently. To learn more about our valve offerings or discuss your specific needs with an expert, reach out to the team today.

Comments