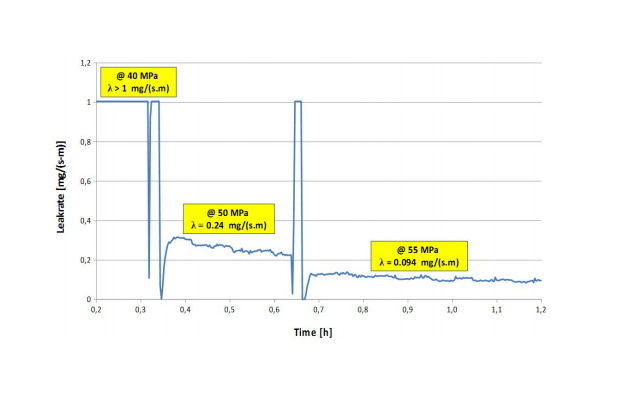

The Nuclear Research Institute operates one of the major high flux MTR type nuclear reactors in the world. In a face of overhaul, the Institute decided to replace 15 year-old gaskets applied to the reactor. The challenge undertaken in this project was to produce a proper welded, corrugated aluminum-jacketed gasket. The gasket had to fulfill very strict requirements in order to create a perfect fit between reactor vessel and its two covers. Leak rate ought to be lower than 0.1 mg/(s•m) at room temperature and 22.5 bar pressure. The test media was nitrogen. To prevent possible damages on the reactor vessel, the gasket had to be designed with only one side corrugated.

The old gasket had been filled with asbestos, but current environmental standards require that gaskets can no longer contain any form of asbestos – for well-known health and safety reasons. The research team at DONIT® proposed a better solution: graphite filler. The Nuclear Research Institute agreed with DONIT®. Based on leak test results for different gasket compositions, a decision was made to use a special graphite composition and geometry to reduce the leak rate of the final gasket.

To get additional information about the gasket behavior inside the flange, Fuji Film was used. This was of great help to understand the correlation between the sealing surface roughness – flatness and the leak rate of the gasket in the real application.

Comments